Press machine Pressgun Picco

Product information

Press machine Pressgun Picco

| Year built (from): | 1.1.2015 |

Trade mark rights exist for this document; for further information, go to viega.com/legal .

Target groups

The information in this instruction manual is directed at the following groups of people:

Heating and sanitary professionals and trained personnel

SHK-Fachkräfte

Individuals without the abovementioned training or qualification are not permitted to mount, install and, if required, maintain this product. This restriction does not extend to possible operating instructions.

The use of Viega products must be carried out in accordance with the general rules of engineering and the Viega instructions for use.

Labelling of notes

Warning and advisory texts are set aside from the remainder of the text and are labelled with the relevant pictographs.

DANGER!

This symbol warns of possible life-threatening injury.

WARNING!

This symbol warns of possible serious injury.

CAUTION!

This symbol warns of possible injury.

NOTICE!

This symbol warns of possible damage to property.

INFO!

This symbol gives additional information and hints.

About this translated version

This instruction for use contains important information about the choice of product or system, assembly and commissioning as well as intended use and, if required, maintenance measures. The information about the products, their properties and application technology are based on the current standards in Europe (e. g. EN) and/or in Germany (e. g. DIN/DVGW).

Some passages in the text may refer to technical codes in Europe/Germany. These should serve as recommendations in the absence of corresponding national regulations. The relevant national laws, standards, regulations, directives and other technical provisions take priority over the German/European directives specified in this manual: The information herein is not binding for other countries and regions; as said above, they should be understood as a recommendation.

Note on use of abbreviated terms

For reading comfort, the following abbreviated terms are used in these instructions for use:

Viega system press machine Pressgun Picco | Press machine |

Viega system press jaws | Press jaws |

Viega system press rings | Press rings |

Viega system press tool | Press tool Combinations of for example:

|

Standards and regulations

The following standards and regulations apply to Germany / Europe and are provided as a support feature.

Regulations from section: Technical data

Scope / Notice | Regulations applicable in Germany |

|---|---|

Oscillation emission value Protection classes | EN 60745‑1 |

Safety advice

WARNING!

General safety advice for electrical tools

Read all safety advice, instructions, figures, and technical data accompanying this electrical tool. Non-compliance with the following instructions may result in electric shock, fire and/or severe injuries.

The term "electrical tools" as used in this safety advice relates to mains-operated electrical tools (with power cable) and battery-operated electrical tools (without power cable).

Retain all safety advice and instructions for future reference.

Workplace safety

a) Keep your working area clean and well lit. Untidy and badly lit working areas pose an accident hazard.

b) Do not use the electrical tool in potentially explosive areas where flammable fluids, gases or dusts are present. Electrical tools generate sparks which may cause the dust or vapours to ignite.

c) Keep children and other persons away while you use the electrical tool. If you are distracted, you may lose control of the tool.

Electrical safety

a) The connection plug of the electrical tool must match the socket. Do not use adapter plugs in combination with electrical tools with protective earthing. Unmodified plugs and matching sockets reduce the risk of electric shock.

b) Do not touch earthed surfaces, for example of pipes, heaters, cookers, and fridges. Increased risk of electric shock if your body is earthed.

c) Keep electrical tools out of the rain and protect them from moisture. Increased risk of electric shock if water gets into an electrical tool.

d) It is forbidden to use the cable to carry the electrical tool or hang it up, or to remove the plug from the socket by pulling at the cable. Keep the cable away from heat, oil, sharp edges, or moving equipment parts. Damaged or tangled connection cables increase the risk of electric shock.

e) When using electrical tools out of doors, only use extension cables suitable for out-of-door use. Using extension cables suitable for out-of-door use reduces the risk of electric shock.

f) If you cannot avoid using the electrical tool in a damp environment, use a residual-current circuit breaker. Using a residual-current circuit breaker reduces the risk of electric shock.

Safety of persons

a) When working with an electrical tool, be attentive, mind what you are doing, and use your common sense. Do not use an electrical tool when you are tired or under the influence of drugs, alcohol, or medication. When using an electrical tool, one second of carelessness may result in severe injury.

b) Wear personal protective equipment. Always wear protective glasses. Depending on the type and application of the electrical tool, you can reduce the risk of injury by wearing personal protective equipment such as dust mask, anti-slip safety shoes, hard hat or hearing protection.

c) Avoid accidental startup of the electrical tool. Ensure that the electrical tool is switched off before you connect it to the mains and/or the battery, take it in your hands or carry it. Having your finger on the switch while you carry the electrical tool, or connecting it to the mains while it is switched on may result in accidents.

d) Before switching the electrical tool on, remove adjusting tools or fork spanners. An adjusting tool or wrench in a rotating device component may cause injuries.

e) Avoid abnormal body postures. Ensure safe footing and a good balance at all times. This helps you to control the electrical tool if an unexpected situation occurs.

f) Wear suitable clothing. Do not wear loose clothing or jewellery. Keep hair, clothes and gloves away from moving components. Loose clothing, jewellery or long hair may get caught in moving components.

g) If the tool is equipped for the connection of dust extraction and collection devices, ensure that these devices are mounted and are used properly. Using dust extraction may reduce the hazards posed by dust.

Using and handling electrical tools

a) Do not overload the tool. Use the electrical tool intended for the task you are doing. For better results and more safety, use the appropriate electrical tool in the specified power range.

b) Do not use an electrical tool with a defective switch. An electrical tool which cannot be switched on or off is dangerous and must be repaired.

c) Pull the plug from the socket and/or remove the battery before adjusting the device settings, changing accessories or putting the tool away. This precaution prevents accidental startup of the electrical tool.

d) When not in use, electrical tools must be stored out of the reach of children. Do not allow persons the use of the tool who are not familiar with it and who have not read these instructions. Electrical tools are dangerous if used by inexperienced persons.

e) Maintain the electrical tool carefully. Check whether moving tool components work smoothly and are not jammed, whether parts are broken or damaged in such a way that the proper function of the electrical tool is impaired. Have damaged components repaired before using the electrical tool. A lot of accidents are caused by improper maintenance of electrical tools.

f) Use electrical tools, accessories, tool bits etc. as specified in these instructions. Take the working conditions and the task at hand into consideration. Using electrical tools for other than the intended use may result in dangerous situations.

Using and handling battery-operated tools

a) To charge the batteries, only use the chargers recommended by the manufacturer. Chargers intended for a certain type of batteries pose a fire risk if used for other batteries.

b) To power the electrical tool, only use the batteries intended for the respective tool. Using other batteries poses a risk of injury and fire.

c) When not in use, keep the battery away from paperclips, coins, keys, nails, screws or other small metal objects which might make a connection from one contact to the other. Short-circuits between the battery contacts may result in burn injuries or fire.

d) Misuse may result in fluid leaking from the battery. Avoid any contact with battery fluid. Rinse with water after any accidental contact. If battery fluid gets into your eyes, rinse with water and seek medical advice. Leaking battery fluid may cause skin irritation or burn injuries.

Service

a) Only commission qualified experts to repair your electrical tool, and have them use original spare parts at all times. This ensures that your tool remains safe.

b) If the connection cable needs replacing, have the repair done by the manufacturer or an official service point to avoid safety risks.

Intended use

Areas of use

The Viega system press machine Pressgun Picco is intended for pressing press connectors into the respective piping systems. In combination with Viega press jaws, the press tool is suitable for use with all Viega sanitary and heating installation systems up and including dimension 35.

Product description

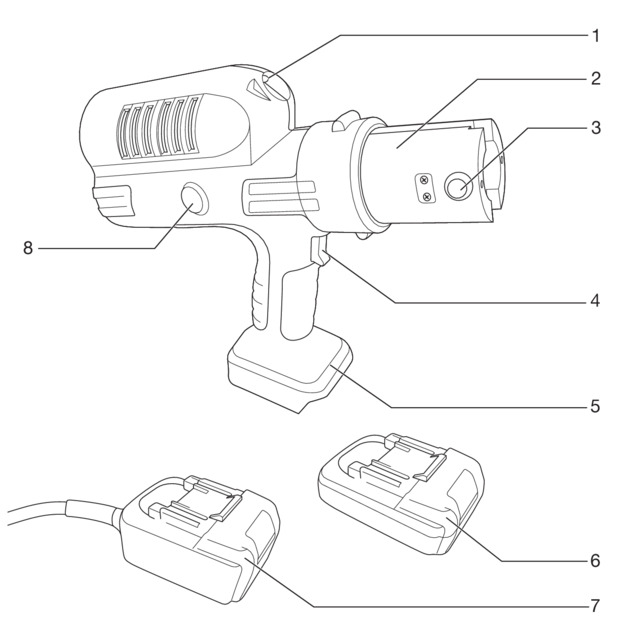

Overview

- 1 - LED lamp

- 2 - cylinder head with press jaw fixture (180° rotatable)

- 3 - retaining bolt

- 4 - Start button

- 5 - bracket for battery or power pack

- 6 - battery (depends on scope of delivery)

- 7 - power pack (depends on scope of delivery)

- 8 - Button for manual release

Scope of delivery

Refer to the model number to see the scope of delivery of your press machine in the table below:

Model number |

|---|

Pressgun Picco |

Press jaw set (dimensions 15 / 22 / 28) |

Press jaw set Raxofix (dimensions 16 / 20 / 25) |

Lithium ion battery (18 V / 2.0 Ah) |

Battery charger (230 V/18 V) |

Case with space saver for power pack |

Instructions for use |

2489.1 | 5389.1 | 2489.2 |

|---|---|---|

X | X | X |

X | - | - |

- | X | - |

X | X | X |

X | X | X |

X | X | X |

X | X | X |

Technical data

The product has the following technical data (approximate values):

Press machine

Nominal capacity |

|---|

voltage |

Machine supervision |

Noise level |

Uncertainty |

Oscillation level |

Uncertainty (K) |

Power transmission |

Shearing force at piston |

Power-on time |

Weight with battery |

270 W |

18 V DC |

electronic |

72 db (A) |

3 db (A) |

< 2.5 m/s2 |

1.5 m/s2 |

hydraulic |

24 kN |

maximum three pressings per minute (≤ DN 28) |

2.6 kg |

The specified oscillation emission value was measured pursuant to the applicable directives and is suitable for comparing the machine with other electrical tools, see Regulations from section: Technical data .

Data on the oscillation emission value (reference period 8 h):

defines a per-day threshold value

> 2.5 m/s2

per-day exposure limit

max. 5 m/s2

Power pack – depending on scope of delivery

The power pack is a voltage transformer which transforms the mains voltage from 230 V AC current to 18 V DC current. Use the connection cable comprised in the delivery to plug the power pack in the socket provided on site.

Input |

|---|

Tolerance range |

Frequency |

Output |

Dimensions (L x W x H) |

Weight |

Cable length |

Overheat protection |

Short-circuit proof |

Overload protection |

Double insulation |

Operating temperature |

Storage |

220–240 V AC |

±5 % |

50–60 Hz |

18 V DC / max. 33 A |

124 x 78.5 x 73 mm |

1 kg |

4.95 m |

100 °C / power pack switched off |

45 A |

provided |

provided |

-10 °C up to +60 °C |

dry, up to 65 °C |

Battery – depending on scope of delivery

Battery technology |

|---|

Capacity |

Charger |

Charging time |

Lithium ions |

18 V / 2.0 Ah 18 V / 4.0 Ah |

Original charger (Viega) |

45 min. (18 V / 2.0 Ah) 60 min. (18 V / 4.0 Ah) |

Charger – depending on scope of delivery

Input |

|---|

Tolerance range |

Frequency |

Input current |

Output |

Battery technology |

Weight |

Dimensions (L x W x H) |

120 V AC or 230 V AC |

±10 V |

50–60 Hz |

max. 1.0 A |

18 V DC |

Lithium ions |

0.73 kg |

153 x 142 x 94 mm |

Operating mode

The Pressgun Picco is an electro-hydraulically operated press machine. Pressing is enabled by switching the machine on and pressing the Start button. The hydraulically operated roller head moves forwards into the press jaw and closes it with a power of 24 kN. This presses the press connector into the pipeline.

The Pressgun Picco is operated at 18 V DC voltage. The power is supplied via battery or power pack.

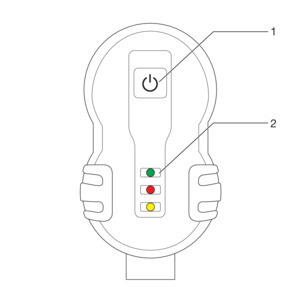

Control elements and indicators at the press machine

LED indicators

- 1 - On / Off button

- 2 - LED indicators

To avoid faulty operation and ensure perfect pressing, the press machine has an electronic monitoring function. LEDs indicate the operating status and any machine malfunction.

The following are monitored:

retaining bolt

Pressing time

Voltage / battery capacity

Service interval

Operating temperatures

Significance of the LEDs

LED | Status | Description |

|---|---|---|

Green  | flashing | Low battery charge level – Recharge battery. |

lit up | Machine is ready for operation. | |

Red  | flashing | Machine is blocked – Slide in retaining bolt. |

lit up | Outside of the temperature range (-5 to 50°C) | |

yellow  | flashing | 30,000 strokes reached / exceeded – Safety shutdown after further 2,000 pressings |

lit up | Machine is blocked – Machine is defective or 32,000 strokes reached. |

On / Off button

Use the On / Off button to switch the press machine on and off.

Keep the On / Off button pressed to check the LED indicators for proper function.

INFO!

The press machine switches off automatically after ten minutes if it is not used after switch-on.

Button for manual release

In case of interruption of the power supply during pressing, press the button for manual release to return the roller head to its initial position.

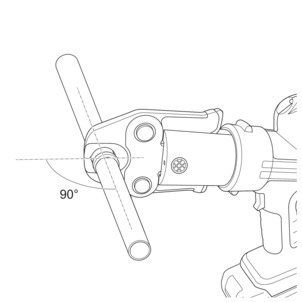

Rotatable cylinder head

The press jaw fixture in the front part of the cylinder head is 180° rotatable to allow for flexible alignment of the press jaws to the pressing point.

Handling

Transport and storage

NOTICE!

Transporting and storing the battery

Observe the manufacturer's instructions for transport and storage.

DANGER!

Risk of crushing!

Risk of getting your fingers and hands crushed.

Store the press machine out of the reach of children and unauthorized persons.

Observe the following instructions for transport and storage of the press machine:

Disconnect the press machine from its power supply.

Store the press machine in the case comprised in the delivery in a dry and frost-protected place.

INFO!

The lithium ion rechargeable battery will need approx. five complete charging and discharging cycles to reach its full capacity.

Protect the press machine and accessories from the following external influences:

Shocks

Wetness and moisture

Dust and dirt

Frost and extreme heat

Chemical solutions and vapours

The press machine has a high level of EMC protection. If the press machine is nevertheless switched off by electromagnetic waves, briefly disconnect the machine from its power supply. This usually remedies the fault. If not, remove the source of the interference.

Commissioning

DANGER!

Danger due to electrical current

An electric shock can lead to burns and serious injury and even death.

Before using the power pack, check that the mains cable is intact.

Pull the mains plug before removing the power pack from the press machine.

Do not place the press machine on a wet underground while the power pack is connected to the mains.

CAUTION!

Risk of crushing from operating the press machine without press jaw.

If no press jaw is inserted, your fingers may get caught in the danger zone and get crushed when the press machine starts up.

Never use the press machine without the press jaw inserted.

Do not reach your fingers into the danger zone.

-

Check the scope of delivery.

-

Insert the power pack or the fully charged lithium ion rechargeable battery into the mounting bracket at the handle.

-

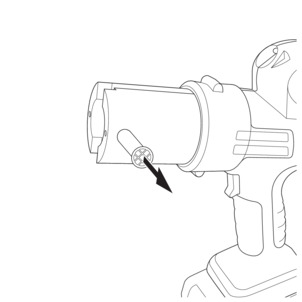

Pull out the retaining bolt at the press jaw fixture.

-

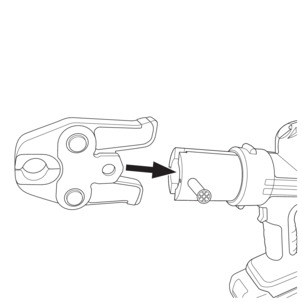

Insert the press jaw in the press jaw fixture of the cylinder head.

INFO!The Figures show an example for the use of a press jaw. Hinged adapter jaws can be used in the same way.

-

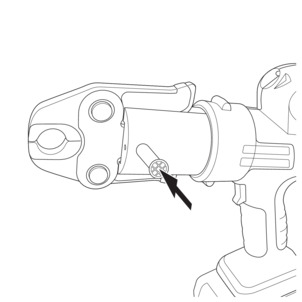

Slide the retaining bolt in as far as it will go.

-

Press the On / Off button.

-

The green LED is lit. The press machine is ready for operation.

Carrying out the pressing process

CAUTION!

Risk of injury due to improper operation

Risk of getting your fingers and hands crushed.

Never start the press machine without the press jaw inserted.

During pressing, do not reach into the range of the advancing and retracting roller head.

For safe operation, hold the press machine tight at the handle and at the machine head.

NOTICE!

Damage to objects due to damages press jaws

Using a defectively, incorrectly dimensioned, or worn press jaw may result in incorrect pressing.

Before using the press jaw, check it for visible defects.

Only use faultless press jaws of a suitable size.

INFO!

The press jaw must be able to lock properly during pressing.

Ensure that there is sufficient room at the pressing point.

Keep the press jaw contour and the area around the pressing point free of dirt.

Requirements:

The press machine is ready for operation; the green LED is lit.

You have properly inserted a press jaw.

-

Check whether the nominal width of the press connector matches the nominal width of the press jaw.

-

Fit the press machine with the press jaw inserted accurately and at a right angle to the pipe axis on the press connector.

-

Keep the Start button pressed until the automatic process starts.

-

As soon as the press machine builds up pressing force, it automatically carries out and completes pressing until the entire press stroke has been carried out.

-

The pressing is completed after full retraction of the roller head. Open the press jaw and loosen it from the press connector.

INFO!

In case of interruption of the power supply during pressing, press the button for manual release to return the roller head to its initial position. Next, remove the incompletely pressed connector from the installation and repeat pressing with a new connector.

Aborting the pressing process

When the roller head has not touched the press jaw yet and no pressing force has been built up, simply let go of the Start button to abort pressing.

Next, actuate the button for manual unlocking and move the roller head back to the starting position.

After the machine has started the automatic process, pressing can only be aborted by actuating the button for manual unlocking.

Troubleshooting

In case of malfunction, check the following potential causes:

Malfunction | Cause | Remedy |

|---|---|---|

Actuating the Start button does not trigger pressing. | The press machine is not switched on. | Press the On / Off button. The green LED is lit. |

The battery is too weak. | Fully charge the battery. | |

The battery or power pack is not properly inserted. | Check that it is properly inserted in the mounting bracket. | |

The mains cable of the power pack is not connected to the mains. | Connect it to the power supply. | |

The power supply is not correct. | Establish the power supply as specified by the manufacturer. |

If the press machine does not start up after taking the above-named measures, please contact an authorised service point ( Service partners ).

Care and maintenance

The tools are subject to normal wear and tear; for this reason, they must be maintained in regular intervals. The maintenance / servicing of the tools must be carried out by service partners authorised by Viega. See Inspection and maintenance .

Cleaning the press tools

Press machine

NOTICE!

Damage due to fluids

Make sure that no fluids get inside the press machine. Never dip the press machine into fluids.

Requirements:

The press machine is de-energised (disconnected from the mains, or battery removed).

No press jaw is inserted.

-

Wipe the press machine down with a slightly damp cloth.

-

Dry-clean the press rolls from the roller head and wipe them with maintenance oil (article no. 667 924).

Press jaws and press rings

-

Remove any dirt and metal residues from the press jaw or press ring.

-

Remove any deposits in the press contour (e.g. with Viega cleaning fleece, art. no. 104 412).

-

Lubricate the joints and moving components with maintenance oil (article no. 667 924).

-

Then, thinly coat the press jaw or press ring with maintenance oil (article no. 667 924). Let it soak briefly, then wipe the part down with a lint-free cloth.

Performing checks

For trouble-free operation, perform checks in regular intervals:

-

After every use, check the pressing geometry of press jaws and press rings for damage or visible wear.

-

Check the press jaws and press rings for smooth operation.

-

Check all press jaws and press rings for proper function by carrying out a test pressing with press connector inserted. The press jaw must lock completely to ensure proper pressing.

In case of malfunctions, contact an authorised service partner.

Inspection and maintenance

Press machine

The functional safety and permanent leak tightness of the Viega press connector systems primarily depends on the functional and operational safety of the Viega system press tools, i.e. the Viega press machine plus Viega system press jaw, ring, chain, and hinged adapter jaw. The Viega system press tools have been specifically designed for and adapted to the installation of the Viega press connector systems. Viega does not check whether these system press tools can be used for pressing other manufacturers' systems. In particular, no statement can be made on whether it is possible to create permanently leakproof connections in this way.

NOTICE!

Do not attempt to carry out the repair yourself but have it done by an authorized service partner.

Service information at the machine

Yellow LED | Cause | Consequences |

|---|---|---|

flashing | 30,000 pressings made | Safety shutdown will take place after further 2,000 pressings. |

lit up | 32,000 pressings made | The electronic monitoring function will shut the machine down for safety reasons. Send the device in to your local service partner for inspection and maintenance. |

Maintenance interval

Hydraulic oil is subject to a natural ageing process. Viega recommends to have the machine inspected and maintained at least every four years.

In case of malfunction, the electronic monitoring function will automatically lock the press machine. Please contact an authorized service partner.

Press jaws and press rings

The Viega system press jaws and system press rings have a label showing the date when the next maintenance is due (e.g. 1st quarter 2021). Have your machine serviced when due to ensure safety and availability.

Service partners

For maintenance and repair of the Viega system press tools, contact the service partner in your country.

Country code | Company | Address / contact information |

|---|---|---|

A | König & Landl GmbH | Döblinger Hauptstrasse 15, 1190 Wien +43 (1) 4797484‑13 /sth@koenig-landl.at |

AUS | Nepean Boltmaster Pty Ltd ABN | 42 Borec Rd, Penrith NSW 2750 +61 (2) 4722 3034 /warren@nepbolt.com.au |

Allied Power Tools Pty. Ltd. | 12/76 Rushdale St, Knoxfield, VIC 3180 +61 (3) 9764 2911/alliedservice@aanet.com.au | |

B | OMICRON-Benelux bvba | Grote Steenweg 116, 3454 Rummen-Geetbets +32 (11) 58 43 50 /rudy.massa@omicron-weldingtechnology.com |

CN | 德房家(中国)管道系统有限公司 | 无锡市锡山区万全路 30 号平谦国际现代产业园 P 栋 400 0688 668/Dong.ji@viega.cn |

Viega (China) Plumbing Systems Co., Ltd. | Building P, Pingqian International Modern Industrial Park, No. 30 Wanquan Road, Xishan District, Wuxi, China (214107) 400 0688 668/Dong.ji@viega.cn | |

CZ / SK | Mátl & Bula, spol. s r.o. | Stará pošta 750, 664 61 Rajhrad u Brna +420 547 424 424 /info@matl-bula.cz |

D | Hans-Joachim Voigt & Sohn | Nordlichtstrasse 48/50, 13405 Berlin +49 (30) 413 4041 /m.sturtz@voigt-und-sohn.de |

Hamburger-Hochdruck-Hydraulik GmbH | Billwerder Billdeich 601c, 21033 Hamburg +49 (40) 7511 900 /Service@HHHydraulik.com | |

Hamburger-Hochdruck-Hydraulik GmbH – Süd | Neue Gautinger Str. 21, 82110 Germering, +49 (89) 130 111 03 /Service@HHHydraulik.com | |

DK | Scherer`s Elektro ApS | Resenbrovej 4, 2610 Rodovre +45 (44) 843738 /Steffen@scherers-elektro.dk |

E | Tecno Izquierdo S.L. | Avda. del Manzanares 222, 28026 Madrid +34 (914) 759158 /tecno.izquierdo@telefonica.net |

F | PLASTIPRO | 245 boulevard de l'Europe, 62118 Monchy-le-Preux +33 (361) 47 40 45 /contact@sarl-plastipro.fr |

FN | Sähköhuolto Tissari Oy | Poijutie 3, 70460 Kuopio + 358 (17) 26 48 500 /osmo.tissari@sht.fi |

GR | Ergon Equipment A.E.T.E. | 102 Kleisthenous & Papafiessa Str, 153 44 Athens +30 (210) 604945 4 /astathis@ergon.com.gr |

I | Elmes KG | Via Artigianale Nord, 6, 39044 Neumarkt +39 (0471) 813399 /info@elmes.it |

I | O.R.E. s.r.l. | Via Sassonia, 16/G, 47900 Rimini +39 (0541) 741003 /info@oreutensili.com |

JP | Toyo Kiko Inc. | 717‑5 Shimokuya-machi, 378‑0061 Numata-shi +81 (278) 24 41 77 /r.adachi@toyo-fit.co.jp |

NO | Grønvold Maskinservice A/S | Brobekkveien 104 A, 0613 Oslo +47 (23) 05 06 40 /Terje@gronvoldmaskin.no |

NL | MG Service | Canadabaan 2, 5388 RT Nistelrode +31 (412) 617 299 /info@mgservice.nl |

RU | KONTURS-SDM | Московская область, Солнечногорский район, Ленинградское шоссе, 34 км., стр. 15 (полигон МАДИ) +7 (499) 702‑45-88 / remont@konturs-sdm.ru |

S | AB Lindströms Elverkstad | Propellervägen 7, 39241 Kalmar +46 (48) 018877 /Fredrik.Greiff@lindstroms-elverkstad.se |

UK | MEP LLA Glasgow - Depot 190 | Unit K, Ashley Drive Bothwell, G71 8BS Glasgow +44 (1698) 740047 /angela.hepburn@vpplc.com |

Broughton Plant Hire | Unit 10, Trade City, Ashton Road, RM3 8UJ Romford, Essex +44 (1708) 383350 /steve@mbroughtonltd.co.uk |

Disposal

For environmentally compatible disposal, send the press machine to your next service partner or give it to a recycling company. Do not dispose of the press machine in the household rubbish and do not scrap it.