Care for Viega system press tools

Product information

Care for Viega system press tools

Trade mark rights exist for this document; for further information, go to viega.com/legal .

Target groups

The information in this instruction manual is directed at the following groups of people:

Heating and plumbing experts and trained personnel

Individuals without the abovementioned training or qualification are not permitted to mount, install and, if required, maintain this product. This restriction does not extend to possible operating instructions.

The use of Viega products must be carried out in accordance with the general rules of engineering and the Viega instructions for use.

Labelling of notes

Warning and advisory texts are set aside from the remainder of the text and are labelled with the relevant pictographs.

DANGER!

This symbol warns of possible life-threatening injury.

WARNING!

This symbol warns of possible serious injury.

CAUTION!

This symbol warns of possible injury.

NOTICE!

This symbol warns of possible damage to property.

INFO!

This symbol gives additional information and hints.

About this translated version

This instruction for use contains important information about the choice of product or system, assembly and commissioning as well as intended use and, if required, maintenance measures. The information about the products, their properties and application technology are based on the current standards in Europe (e.g. EN) and/or in Germany (e.g. DIN/DVGW).

Some passages in the text may refer to technical codes in Europe/Germany. These should serve as recommendations in the absence of corresponding national regulations. The relevant national laws, standards, regulations, directives and other technical provisions take priority over the German/European directives specified in this manual: The information herein is not binding for other countries and regions; as said above, they should be understood as a recommendation.

Intended use

Areas of application

Viega system press tools have been specifically designed for and adapted to the installation of the Viega press connector systems. If systems by other manufacturers are used, Viega cannot provide any warranties.

INFO!

Please fulfil your duty of care and follow these care instructions. In this way, you achieve maximum functional safety between the maintenance intervals. The general principle "safety through maintenance" applies. If the advice is not followed, no responsibility for personal injury can be accepted.

Product description

Overview

Model number | |

|---|---|

| 2296.2, 2496.1 |

| 2497.2XL, 2497.3XL, 4296.1XL |

| 2297.1 XL |

| 2297.2XL, 2297.3XL |

| 2299.2, 2299.4, 2299.41, 2299.6, 2299.62, 2299.7, 2299.8, 2299.81, 2299.9, 2484.7, 2484.9, 2489.9, 2799.7, 4284.9, 4299.95384.7, 5399.7 |

| 2499.2, 2499.1 |

| 2296.1, 2296.4, 2496.3, 2496.5, 5396.1 |

| 9696.1, 9696.6, 9696.7 |

| 9796.1, 9796.7 |

| 4296.4XL |

| 9796.7 |

| 4278.90 |

Handling

Transport and storage

Clean the press tools after use and lightly oil.

Store the press tools in a clean and dry place.

During transport, protect the press tools from mechanical influences.

Care and maintenance

Performing checks

For trouble-free operation, perform checks in regular intervals:

-

After every use, check the press contour of the press jaws, press chains and press rings as well as the ball heads of the hinged adapter jaws and the contact points of the press rings for damage or visible wear.

-

Check the press jaws and press rings for smooth operation.

-

Carry out a test pressing with the press connector inserted, and check the pressing point for formation of burrs.

In case of malfunctions, contact an authorised service partner.

Cleaning the press tools

INFO!

Application and care should be carried out by specialists in compliance with the servicing intervals.

-

Regularly clean the press contours of the press jaws, press rings and press chains with fine steel wool or cleaning fleece in order to remove deposits and prevent corrosion (e.g. using the Viega cleaning fleece, art. no. 104 412).

-

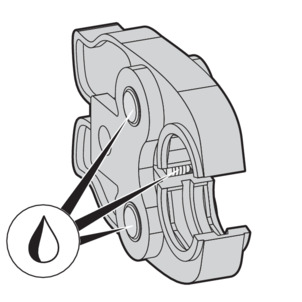

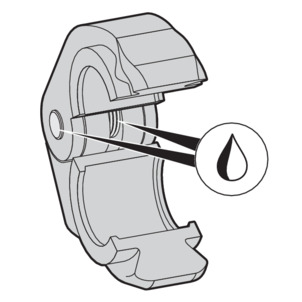

Apply maintenance oil to the hinges and all moving parts (art. no. 667 924). Move the tools and joints while lubricating them.

-

INFO!

Note the pictures in chapter Greasing the lubrication points at the press tools .

-

Then thinly spray the press jaw or press ring with maintenance oil (art. no. 667 924) and let it work for a short time before wiping off with a lint-free cloth.

Every two years, have an authorised service partner (see Service partners ) carry out the maintenance.

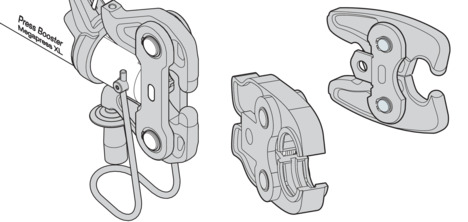

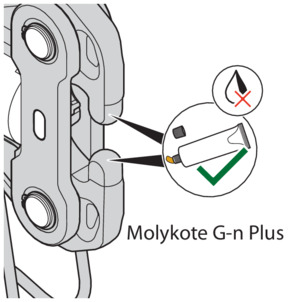

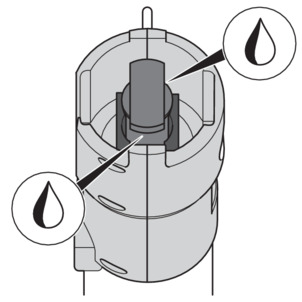

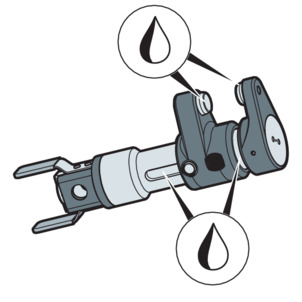

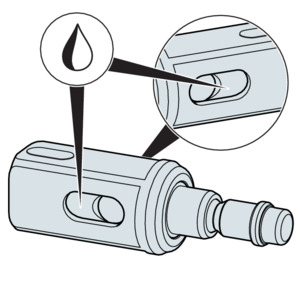

Greasing the lubrication points at the press tools

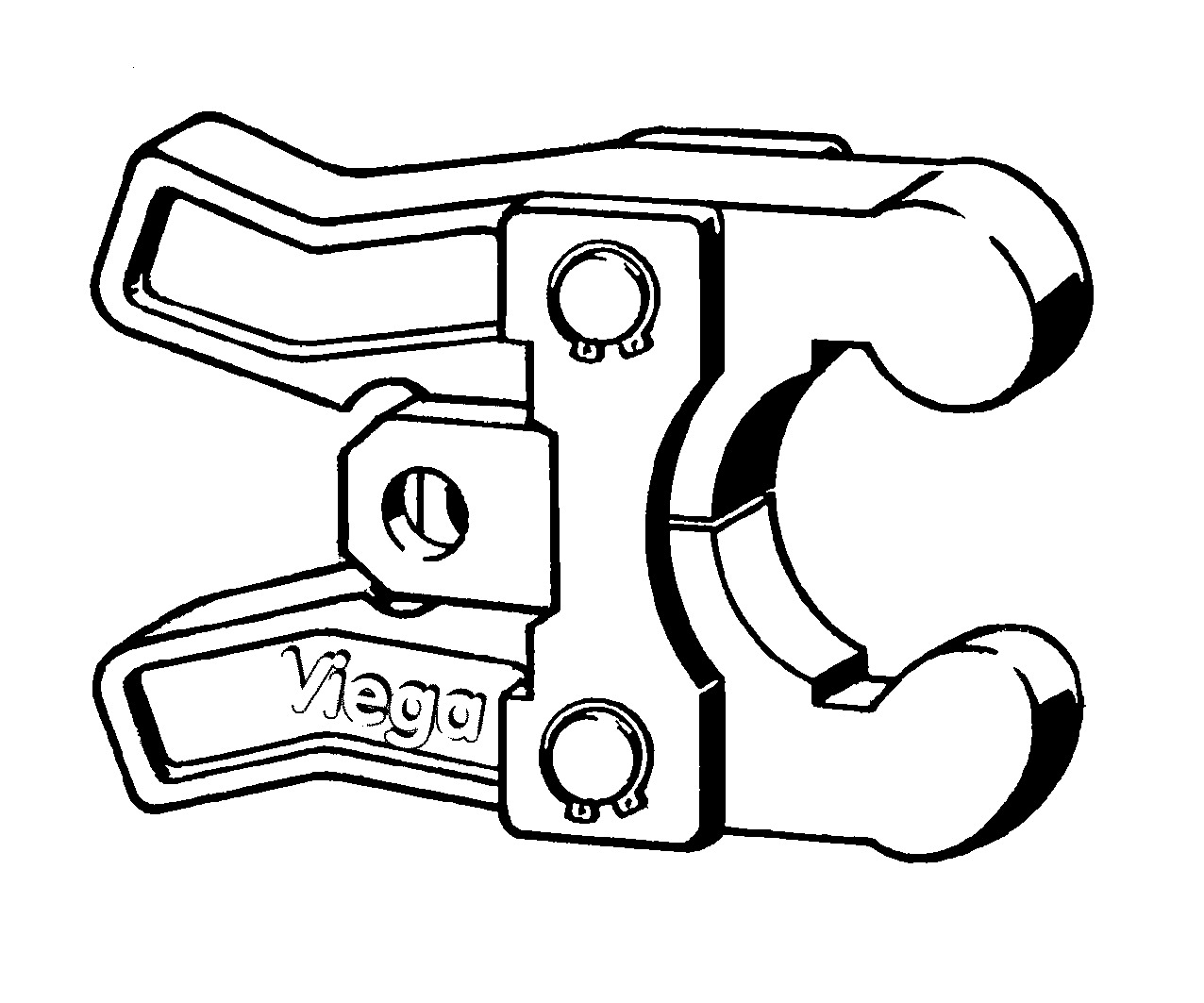

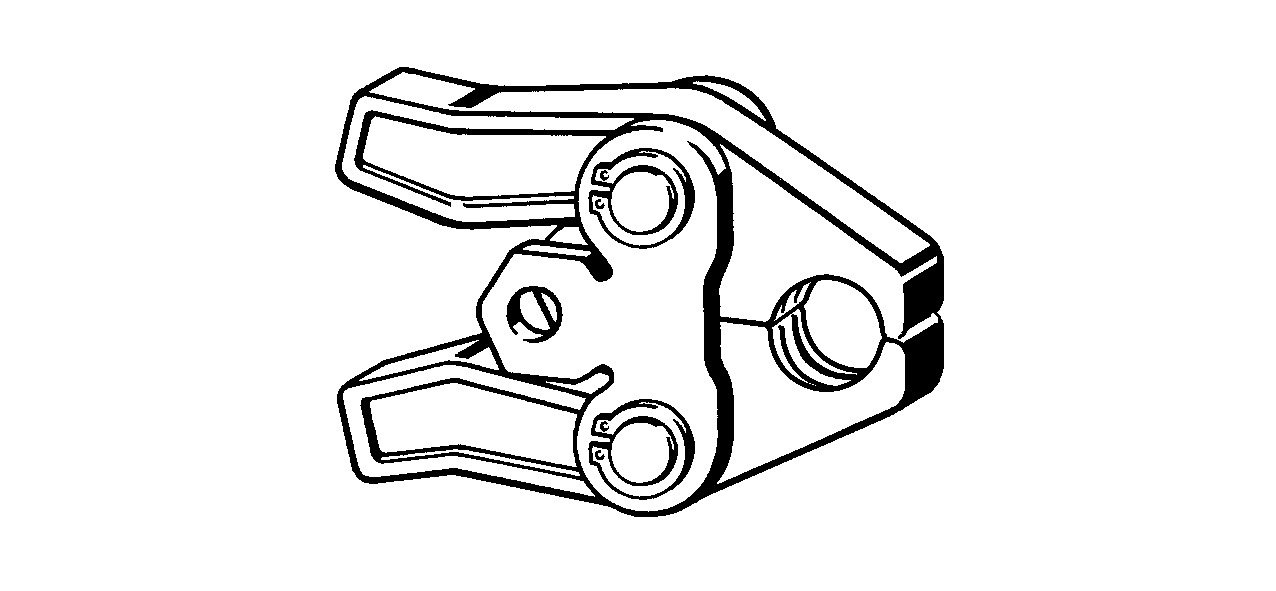

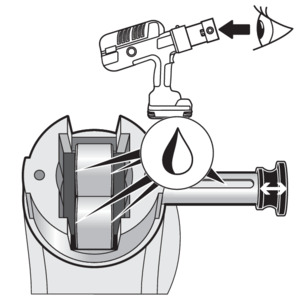

Lubrication points at a press jaw.

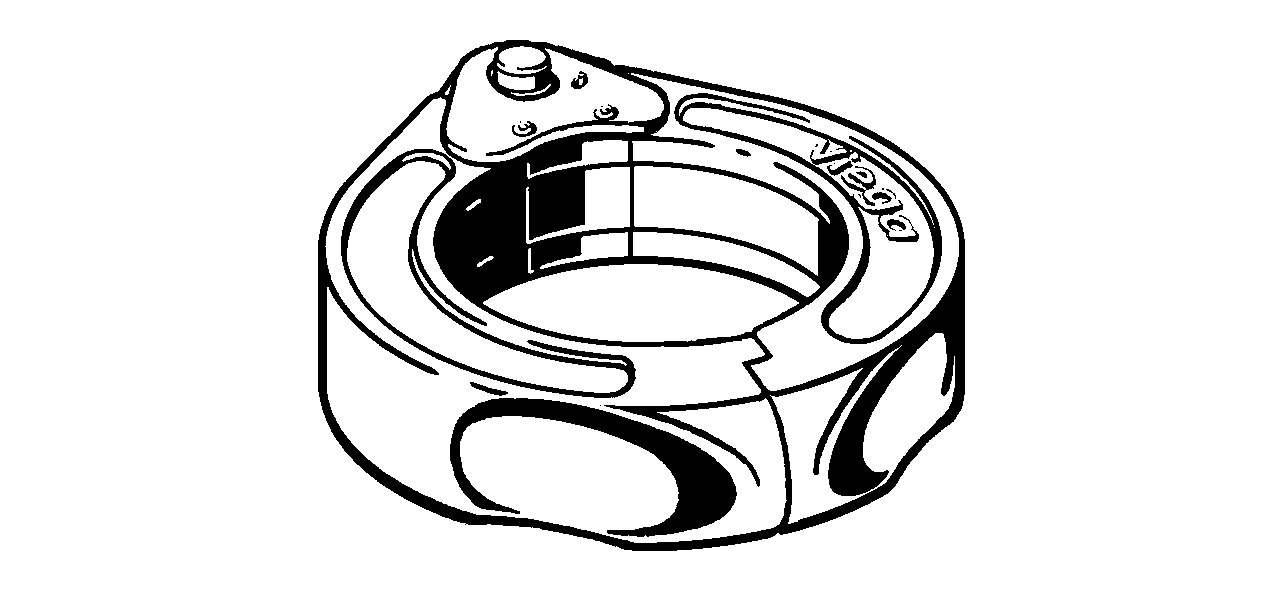

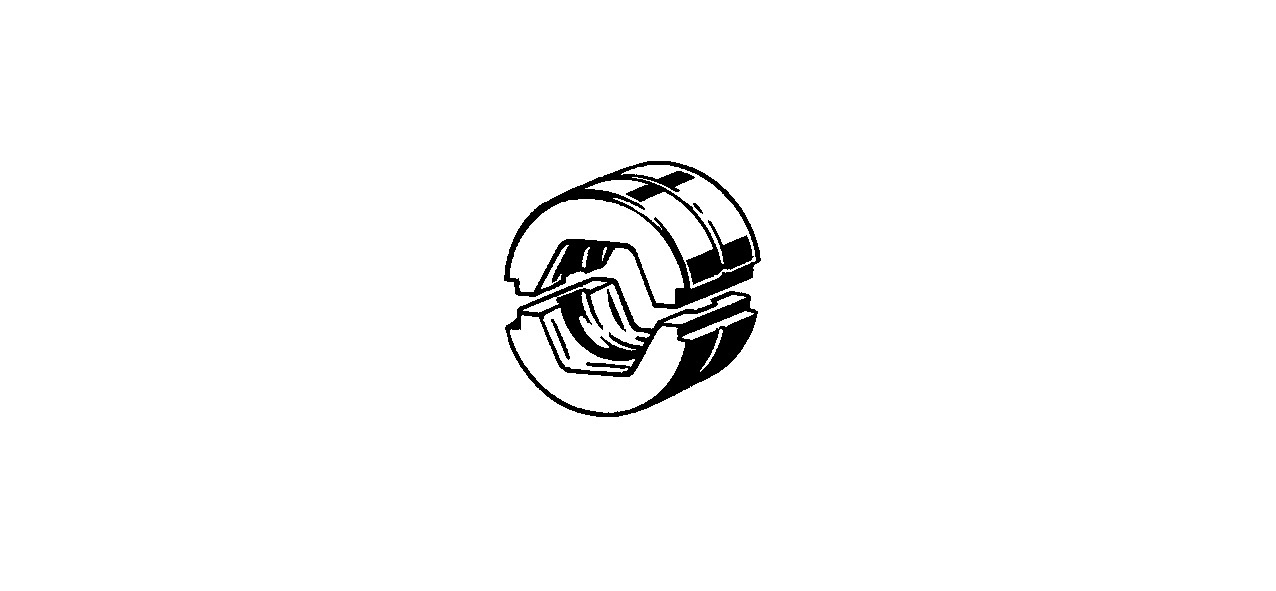

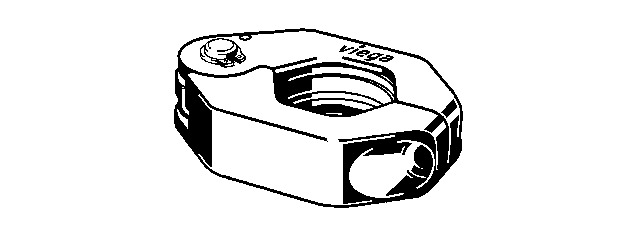

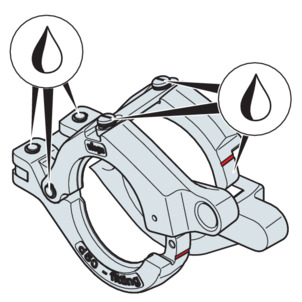

Lubrication points at a press ring.

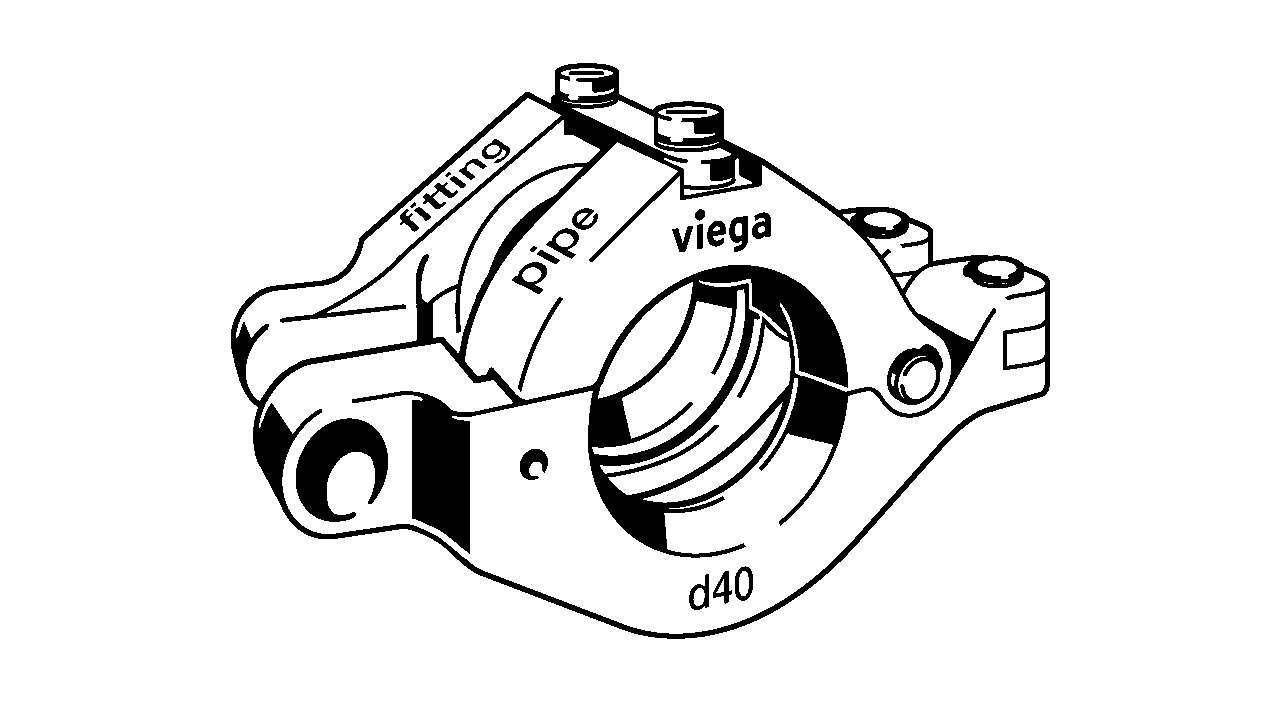

Lubrication points at press machines.

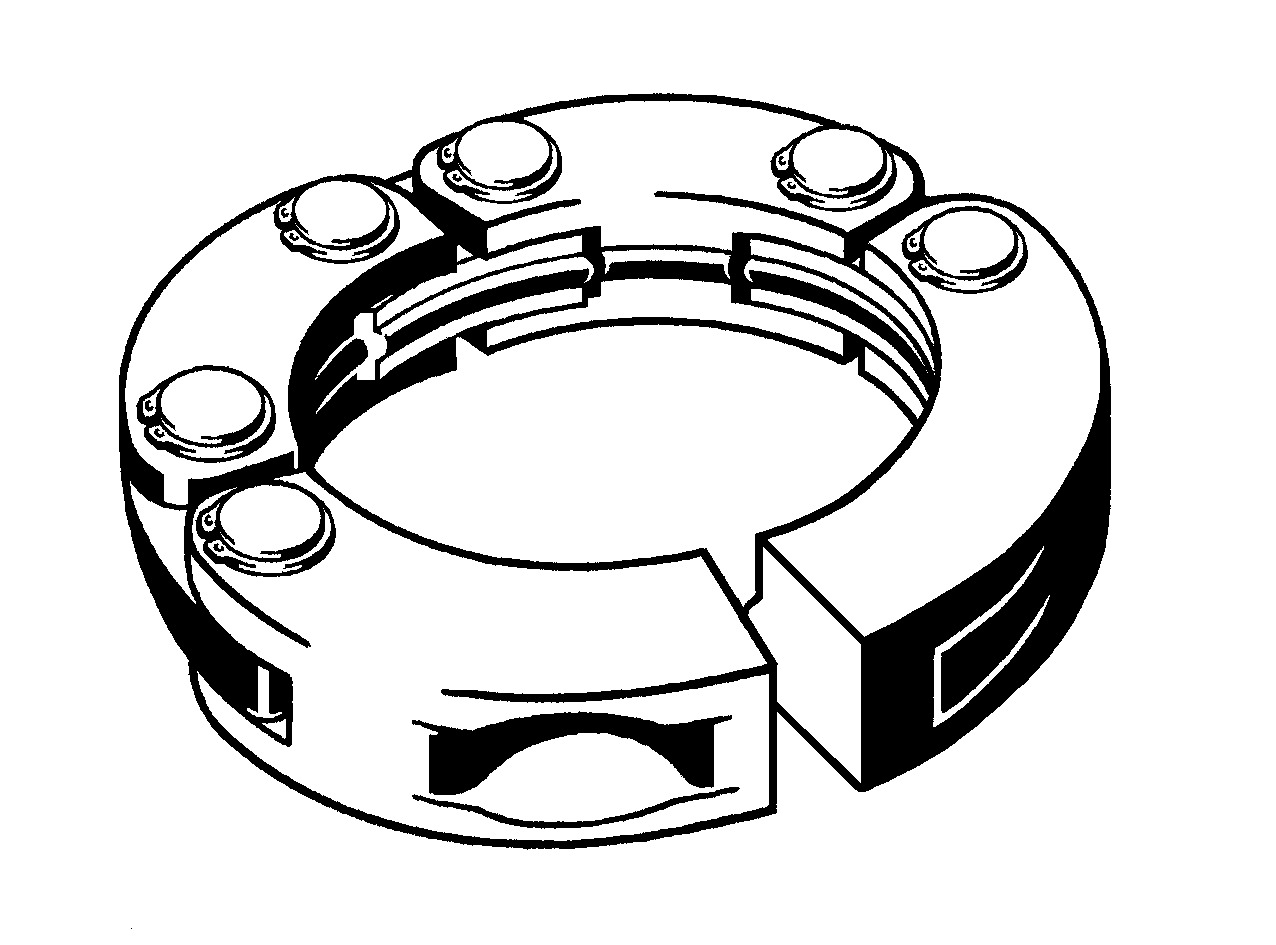

Lubrication points at the press ring Geopress K.

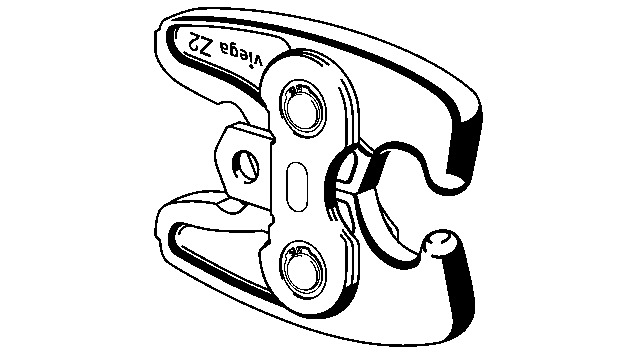

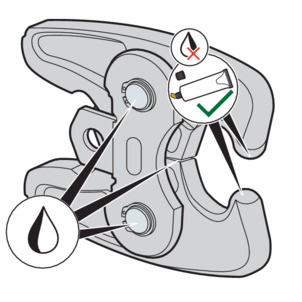

Lubrication points at a hinged adapter jaw Z2.

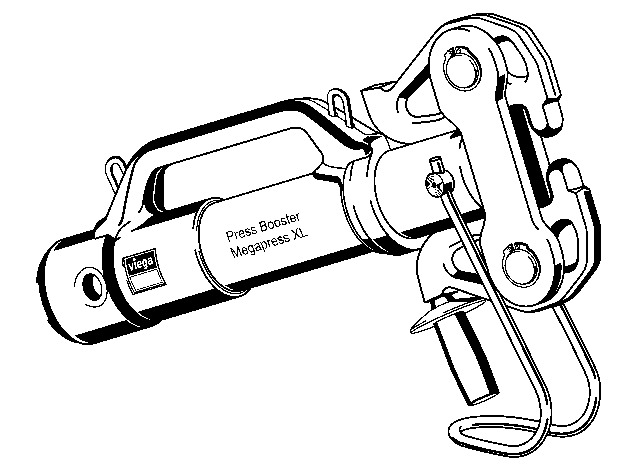

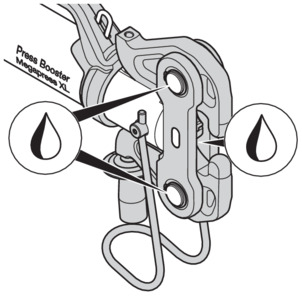

Lubrication points at Press Booster (hinged adapter jaw Z3).

Lubrication points on the ball heads.

Use paste Molykote G-n Plus (art. no. 794 910).

Lubrication points at the press ring drive.

Lubrication points at the press-in tool.

Inspection and maintenance

Viega recommends to have the system press jaws, chains, and rings regularly by a service partner. Moving parts are cleaned and lubricated, press contours are reworked, and the system press jaws, chains and rings are checked for damage and dimensional accuracy.

Service interval of the press machines

Press machine | Service interval |

|---|---|

Pressgun 6 Plus | Can be called up via the Viega Tool Services app or is indicated after 40000 pressings, safety shutdown after a further 2000 pressings or after 4 years at the latest, whichever comes first. |

Pressgun Picco 6 Plus | |

Pressgun 6 | Indication after 30000 pressings, safety shutdown after a further 2000 pressings or after 4 years at the latest, whichever comes first. |

Pressgun Picco 6 | |

Pressgun 6 B | Every 2 years at the latest |

Pressgun 5 | Indication after 40000 pressings, safety shutdown after a further 2000 pressings or after 4 years at the latest, whichever comes first. |

Pressgun Picco and Pressgun 4E and 4B | Indication after 30000 pressings, safety shutdown after a further 2000 pressings or after 4 years at the latest, whichever comes first. |

Type PT3-AH, Picco and type PT3-H/EH | Indication on the LED display after 20000 pressings, safety shutdown after a further 2000 pressings or after 4 years at the latest, whichever comes first. |

Type 1 | At least every 2 years |

Type 2 | Once a year |

Press jaw, ring, chain and hinged adapter jaw | Every 2 years |

Overview of maintenance labels

Until 2023 | from 2023/24 |

|---|---|

|

|

Maintenance label stating the next recommended maintenance date. | Standardised label with QR code. The link leads to the instructions “How to care for Viega system press tools” |

The Viega system press jaws and system press rings have a label showing the date when the next maintenance is due. Respect the maintenance dates in order to guarantee safety and proper function. After completed maintenance, the Viega service partner will apply a new sticker.

Service partners

For maintenance and repair of the press tools, contact the service partner in your country.

Country code | Company | Address/contact |

|---|---|---|

AT | König & Landl GmbH | Döblinger Hauptstrasse 15, 1190 Vienna https://www.koenig-landl.at / sth@koenig-landl.at +43 1 4797484‑13 |

AU | Press Tools Australia Pty Ltd | Unit 23, 35 Sefton Road, Thornleigh NSW 2120 +61 (2) 99 808 440 /service@presstools.com.au |

Allied Service Department | 12/76 Rushdale Street, Knoxfield, Victoria 3180 +61 (3) 9764 2911 /alliedservice@aanet.com.au | |

BE | OMICRON-Benelux | Grote Steenweg 116, 3454 Rummen-Geetbets +32 (11) 58 43 50 /rudy.massa@omicron-weldingtechnology.com |

CN | 德房家(中国)管道系统有限公司 | 无锡市锡山区万全路 30 号平谦国际现代产业园 P 栋 400 0688 668 /tao.wu@viega.cn |

Viega (China) Plumbing Systems Co., Ltd. | Building P, Pingqian International Modern Industrial Park, No. 30 Wanquan Road, Xishan District, Wuxi, China (214107) 400 0688 668 /tao.wu@viega.cn | |

CZ / SK | Mátl & Bula | Stará pošta 750, 66461 Brno +420 5 4723 0048 /info@matl-bula.cz |

DE | Hans-Joachim Voigt & Sohn | Nordlichtstrasse 48/50, 13405 Berlin +49 (30) 413 4041 /m.sturtz@voigt-und-sohn.de |

Hamburger-Hochdruck-Hydraulik GmbH | Billwerder Billdeich 601c, 21033 Hamburg +49 (40) 7511 900 /Service@HHHydraulik.com | |

Hamburger-Hochdruck-Hydraulik GmbH – Süd | Neue Gautinger Str. 21, 82110 Germering, +49 (89) 130 111 03 /Service@HHHydraulik.com | |

DK | Scherer`s Elektro | Valhøjs Alle 171, 2610 Rodovre +45 (44) 843738 /Birgith@scel.dk |

ES | Tecno Izquierdo | Avda. del Manzanares 222, 28026 Madrid +34 (914) 759158 /tecno.izquierdo@telefonica.net |

FR | Plasti Pro | 245 boulevard de l'Europe, 62118 Monchy-le-Preux +33 (361) 47 40 45 /contact@sarl-plastipro.fr |

FI | Sähköhuolto Tissari Oy | Poijutie 3, 70460 Kuopio + 358 17 26 48 500 /info@sht.fi |

IN | Viega India Private Limited | Plot No. E-565, Sanand GIDC Phase - 2, Sanand 382110 +91 997 890 70 44 /Anand.Kurumbhatte@viega.in |

IT | Elmes KG | Via Artigianale Nord, 6, 39044 Neumarkt +39 (0471) 813399 /info@elmes.it |

IT | O.R.E. s.r.l. | Via Sassonia, 16/G, 47900 Rimini +39 (0541) 741003 /info@oreutensili.com |

NO | Grønvold Maskinservice A/S | Brobekkveien 104 A, 0613 Oslo +47 (23) 05 06 40 /Terje@gronvoldmaskin.no |

NL | MG Service | Canadabaan 2, 5388 RT Nistelrode +31 (412) 617 299 /info@mgservice.nl |

PL | Despol Service | Podgórska 3, 02‑921 Warszawa +48 22 6428570 /m.jaworski@despoltm.pl |

PROMOT | ul. Metalowa 9, 87‑800 Włocławek +48 50 433 82 76 /s.grzegorzewski@szczotkiweglowe.pl | |

SE | AGB Service | Flottiljvägen 22, 39241 Kalmar +46 (0) 480 281 74 /anders@agbservice.se |

UK | MEP Hire | Unit K, Ashley Drive Bothwell, G71 8BS Glasgow +44 800 587 5121 /hire@mephire.co.uk |

Broughton Plant Hire & Sales | Unit 10, Trade City, Ashton Road, RM3 8UJ Romford, Essex +44 (1708) 383350 /joe@mbroughtonltd.co.uk |

Disposal

Separate the product and packaging materials (e. g. paper, metal, plastic or non-ferrous metals) and dispose of in accordance with valid national legal requirements.