Easytop extraction valve

Product information

Easytop extraction valve

For the sample extraction of potable water (PWC/PWH/PWH-C) in accordance with PWO

| Year built (from): | 12-07-13 |

Trade mark rights exist for this document; for further information, go to viega.com/legal .

Target groups

The information in this manual is directed at heating and sanitary professionals and trained personnel.

Individuals without the abovementioned training or qualification are not permitted to mount, install and, if required, maintain this product. This restriction does not extend to possible operating instructions.

The installation of Viega products must take place in accordance with the general rules of engineering and the Viega instructions for use.

Labelling of notes

Warning and advisory texts are set aside from the remainder of the text and are labelled with the relevant pictographs.

DANGER!

This symbol warns of possible life-threatening injury.

WARNING!

This symbol warns of possible serious injury.

CAUTION!

This symbol warns of possible injury.

NOTICE!

This symbol warns of possible damage to property.

INFO!

This symbol gives additional information and hints.

About this translated version

This instruction for use contains important information about the choice of product or system, assembly and commissioning as well as intended use and, if required, maintenance measures. The information about the products, their properties and application technology are based on the current standards in Europe (e.g. EN) and/or in Germany (e.g. DIN/DVGW).

Some passages in the text may refer to technical codes in Europe/Germany. These should serve as recommendations in the absence of corresponding national regulations. The relevant national laws, standards, regulations, directives and other technical provisions take priority over the German/European directives specified in this manual: The information herein is not binding for other countries and regions; as said above, they should be understood as a recommendation.

Standards and regulations

The following standards and regulations apply to Germany / Europe and are provided as a support feature.

Regulations from section: Application areas

Scope / Notice | Regulations applicable in Germany |

|---|---|

Planning, execution, operation and maintenance of potable water installations | DIN EN 806, part 1 |

Planning, execution, operation and maintenance of potable water installations | DIN EN 806, part 2 |

Planning, execution, operation and maintenance of potable water installations | DIN EN 806, part 3 |

Planning, execution, operation and maintenance of potable water installations | DIN EN 806, part 4 |

Planning, execution, operation and maintenance of potable water installations | DIN EN 806, part 5 |

Planning, execution, operation and maintenance of potable water installations | DIN EN 1717 |

Planning, execution, operation and maintenance of potable water installations | DIN 1988 |

Planning, execution, operation and maintenance of potable water installations | VDI/DVGW 6023 |

Planning, execution, operation and maintenance of potable water installations | Trinkwasserverordnung (TrinkwV) |

Planning, execution, operation and maintenance of potable water installations | DVGW-Arbeitsblatt W 551 |

Regulations from section: Media

Scope / Notice | Regulations applicable in Germany |

|---|---|

Suitability for potable water | Trinkwasserverordnung (TrinkwV) |

Regulations from section: Product description

Scope / Notice | Regulations applicable in Germany |

|---|---|

Suitability for potable water installations | Trinkwasserverordnung (TrinkwV) |

Suitability for potable water installations | DIN 50930‑6 |

Requirements in plastic components in potable water installations | DVGW-Arbeitsblatt W270 |

Regulations from section: Overview

Scope / Notice | Regulations applicable in Germany |

|---|---|

Inspection requirements | DVGW-Arbeitsblatt W 579 (P) |

Use for regular sampling in public / commercial buildings | DVGW-Arbeitsblatt W 551 |

G-thread | DIN EN ISO 228‑1 |

Regulations from section: Notes on mounting

Scope / Notice | Regulations applicable in Germany |

|---|---|

Placement of the extraction valves | DVGW-Arbeitsblatt W 551 |

Regulations from section: Leakage test

Scope / Notice | Regulations applicable in Germany |

|---|---|

Leakage test for potable water installations | DIN EN 806, part 4 |

Leakage test for potable water installations | ZVSHK-Merkblatt |

Regulations from section: Maintenance

Scope / Notice | Regulations applicable in Germany |

|---|---|

Operation and maintenance of potable water installations | DIN EN 806‑5 |

Intended use

INFO!

Agree the use of the model for areas of application and media other than those described with Viega.

Areas of application

Use is possible in the following areas among others:

Potable water installations

Industrial units

The general rules of engineering and the applicable regulations must be observed for planning, execution, operation and maintenance of potable water installations, see Regulations from section: Application areas .

Media

The model is also suitable for the following media, amongst others:

Potable water without limitations acc. to the applicable directives, see Regulations from section: Media

Maximum chloride concentration 250 mg/l pursuant to applicable regulations, see Regulations from section: Media

Product description

According to the applicable regulations, Easytop system fittings can be used for all types of potable water and are DVGW certified, see Regulations from section: Product description . Their plastic components comply with the KTW recommendation and the requirements pursuant to the applicable regulations.

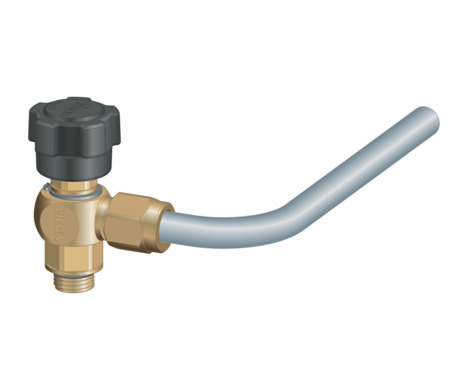

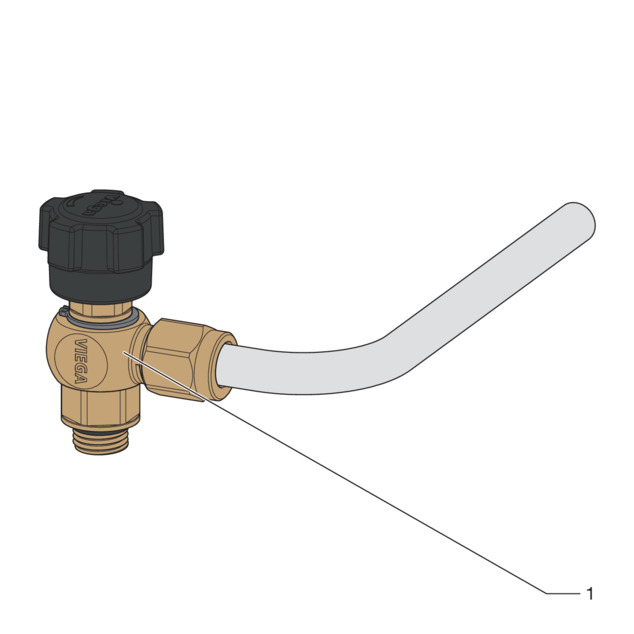

Overview

INFO!

The Easytop extraction valves comply with the test requirements specified in the applicable regulations and are suitable for regular sample extraction in public / commercial buildings, see Regulations from section: Overview .

INFO!

The Easytop system fittings comply with the test requirements specified in the applicable regulations, see Regulations from section: Overview . Sound protection Lap≤ 20 dB(A)

- 1 - actuation unit

The one-piece extraction valve remains permanently in the potable water installation.

The model is equipped as follows:

Extraction valve made of gunmetal/silicon bronze

Outlet pipe made of steel, stainless, rotatable, flame-treatable

Removable handwheel

G-thread pursuant to applicable regulations, see Regulations from section: Overview

The model is available in the following dimension: G ¼.

For use in G ⅜ internal threads, model 2223.5 (Easytop adapter nipple) is available. The Easytop adapter nipple is pre-sealed by means of a Teflon® seal.

Threaded connection

The extraction valve is self-sealing.

G ¼ with O-ring

Compatible components

We recommend to use the model with Easytop fittings.

Please contact the Viega Service Center for questions on this subject.

Technical data

Observe the following operating conditions for the installation of the model:

Operating temperature [Tmax.] |

|---|

Operating pressure [Pmax] |

90 °C |

1.6 MPa (16 bar) |

Information for use

Corrosion

Overground pipelines and fittings in rooms do not normally require external corrosion protection.

There are exceptions in the following cases:

Contact with aggressive building materials such as nitrite or materials containing ammonium

in aggressive surroundings

INFO!

The one-piece Easytop extraction valve made of gunmetal/silicon bronze can be used for all types of potable water.

The chloride concentration in the medium must not exceed a maximum value of 250 mg/l.

This chloride is not a disinfectant, but in fact pertains to the content in sea and table salt (sodium chloride).

Required accessories

An adapter nipple (model 2223.5) is required for the mounting of the model with a G⅜ internal thread.

Handling

Assembly information

Mounting instructions

The positioning of the extraction valve should take place in accordance with the recommendations of the applicable directives; existing testing or drainage openings on fittings can be used, see Standards and regulations .

The extraction valve can be mounted on various axes of rotation in nearly all positions of a system:

360° rotatable outlet pipe

Base unit rotatable through 360° on the actuation unit

Checking system components

INFO!

Do not remove the model from the packaging until immediately before use.

System components may, in some cases, become damaged through transportation and storage.

Check all parts.

Replace damaged components.

Do not repair damaged components.

Contaminated components may not be installed.

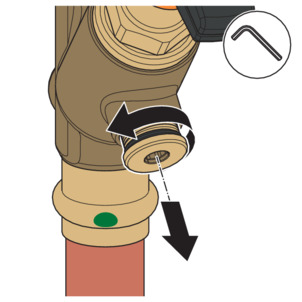

Required tools

The following tools are required for mounting the model:

Allen key (size 5) for drain plug on the Easytop fittings

Open-end spanner (size 17) and if required (size 19) for adapter nipple

Assembly

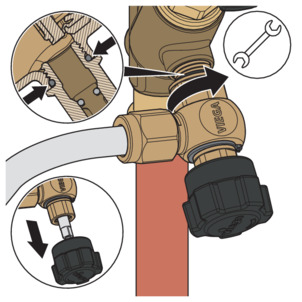

Mounting the extraction valve

Mount extraction valve in a G ¼ internal thread

INFO!

A leakage and functionality test must be carried out after mounting.

Before fitting the extraction valve, check that the system has been depressurised.

-

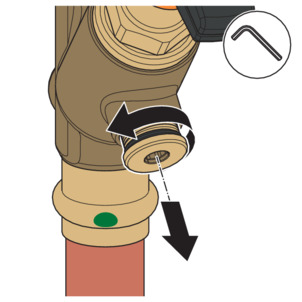

Unscrew the drain plug with an Allen key (SW 5).

-

Screw in the extraction valve with a fork spanner (SW 17).

INFO!The handwheel can be removed in the case of reduced accessibility. By doing that, an additional key surface (size 14) is made available.

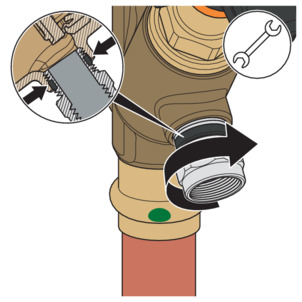

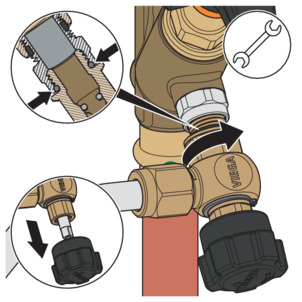

Mounting extraction valve in a G ⅜ internal thread

INFO!

Carry out a leak test and a function test on completion of initial fitting.

Before fitting the extraction valve, check that the system has been depressurised.

-

Unscrew the drain plug with an Allen key (SW 5).

-

Screw in the adapter nipple with a fork spanner (SW 19).

INFO!Screw in the Teflon® seal as far as it will go.

-

Screw in the extraction valve with a fork spanner (SW 17).

INFO!The handwheel can be removed in the case of reduced accessibility. By doing that, an additional key surface (size 14) is made available.

Leakage test

The installer must perform a leakage test before commissioning.

Carry out this test on a system that is finished but not covered yet.

Comply with the general rules of engineering and the applicable directives, see Regulations from section: Leakage test .

Document the result.

Control

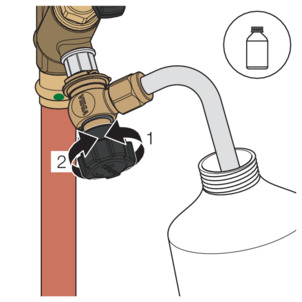

Sample extraction

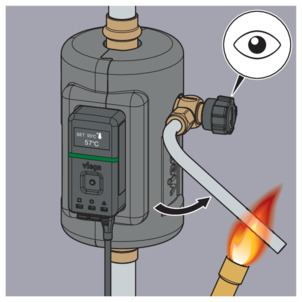

Disinfect outlet pipe

INFO!

Disinfect or sterilise the outlet pipe every time prior to sampling.

The extraction valve can also be operated using a bleeding key when the handwheel is removed.

-

Thermally or chemically disinfect or sterilise the outlet pipe, e.g. using flame treatment.

In the following, thermal disinfection is explained by way of example using the sampling valve on a circulation control valve.

You might need to remove the handwheel in difficult installation situations prior to flame treatment.

Direct contact of the flame with the electronic circulation control valve and the insulation shell will cause damage.

Do not point the flame in the direction of the valve.

-

Turn the outlet pipe away from the electronic circulation control valve and the insulation shell.

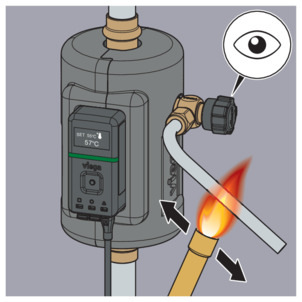

-

Carefully heat the outlet tube with a standard burner (butane / propane burner / soldering flame).

Danger of burns from flame and hot surfaces.

Do not touch hot surfaces or naked flames or come into contact with flammable objects.

-

For even heating of the outlet tube, pass the flame between the tube bend and the outlet in both directions.

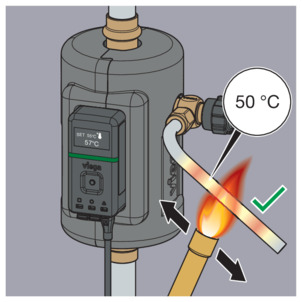

-

Heat the tube evenly. If the outlet pipe is heated evenly and the flame is guided carefully, there is no danger of damaging the valve.

-

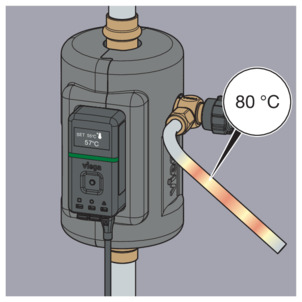

The outlet pipe should reach a temperature of approx. 80 °C. If the flame is guided evenly along the tube, a temperature of approx. 80 °C is reached after approx. 20‑30 seconds with a standard burner.

-

Immediately after flaming and opening the sampling valve, a hissing sound should be audible.

Sample

-

Open the valve using the handwheel and extract a water sample.

-

After extracting the sample, close the valve using the handwheel.

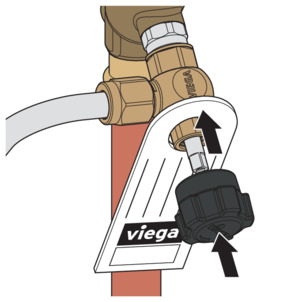

Mounting the signage

INFO!

Sampling points must be labelled in such a way as to avoid confusion and in compliance with applicable guidelines, see Standards and regulations .

The signage (writeable) can be mounted behind the handwheel.

-

Remove the handwheel from the actuation unit.

-

Attach the signage.

-

Re-attach the handwheel.

Disposal

Separate the product and packaging materials (e. g. paper, metal, plastic or non-ferrous metals) and dispose of in accordance with valid national legal requirements.