Smartloop

Tuotetiedot

Smartloop

| Valmistusvuosi (alk.): | 18.6.2003 |

Tätä asiakirjaa koskevat suojaoikeudet, lisätietoja saat osoitteesta viega.com/legal .

Käyttökohteet

Tämän ohjeen tiedot on suunnattu lämmitys- ja saniteettialan ammattilaisille ja opastetulle ammattihenkilöstölle.

Henkilöt, joilla ei ole yllä mainittua koulutusta tai pätevyyttä, eivät saa suorittaa tämän tuotteen asennusta, liitäntää tai mahdollista huoltoa. Tämä rajoitus ei koske mahdollisia käyttöä koskevia ohjeita.

Viega-tuotteiden asennus on suoritettava tekniikan yleisesti voimassa olevia sääntöjä ja Viega-käyttöohjeita noudattaen.

Ohjeiden merkinnät

Varoitukset ja ohjeet on sisennetty muusta tekstistä ja merkitty erityisesti vastaavilla kuvakkeilla.

VAARA!

Varoittaa mahdollisista hengenvaarallisista vammoista.

VAROITUS!

Varoittaa mahdollisista vakavista vammoista.

HUOMIO!

Varoittaa mahdollisista vammoista.

OHJE!

Varoittaa mahdollisista aineellisista vahingoista.

INFO!

Lisäohjeita ja vinkkejä.

Tätä kieliversiota koskeva ohje

Tämä käyttöohje sisältää tuote- tai järjestelmävalikoimaa, asennusta ja käyttöönottoa sekä määräystenmukaista käyttöä sekä tarvittaessa huoltotoimia koskevia tärkeitä tietoja. Nämä tiedot tuotteista, niiden ominaisuuksista ja sovellusteknologioista perustuvat normeihin, jotka ovat parhaillaan voimassa Euroopassa (esim. EN) ja/tai Saksassa (esim. DIN/DVGW).

Joissakin tekstiosioissa saatetaan viitata eurooppalaisiin/saksalaisiin teknisiin määräyksiin. Nämä määräykset toimivat muille maille suosituksina, mikäli niissä ei ole olemassa vastaavia kansallisia vaatimuksia. Voimassa olevilla kansallisilla laeilla, standardeilla, määräyksillä, normeilla sekä muilla teknisillä määräyksillä on etusija tämän ohjeen saksalaisiin/eurooppalaisiin direktiiveihin nähden. Tässä esitetyt tiedot eivät ole sitovia muille maille ja alueille ja ne tulisi ymmärtää tueksi.

Normit ja säännökset

Seuraavat normit ja säännökset koskevat Saksaa/Eurooppaa, ja ne on tarkoitettu tueksi.

Säännökset osiosta: Määräysten mukainen käyttö

Voimassaoloalue/ohje | Saksassa voimassa oleva säännös |

|---|---|

Käyttövesijärjestelmien laatiminen | DIN 1988‑200 |

Käyttövesijärjestelmien laatiminen | EN 806‑2 |

Materiaalin valintaa koskevat säännökset | DIN EN 12502‑1 |

Materiaalin valintaa koskevat säännökset | Metall-Bewertungsgrundlage (UBA) |

Säännökset osiosta: Käyttöalueet

Voimassaoloalue/ohje | Saksassa voimassa oleva säännös |

|---|---|

Käyttövesijärjestelmien suunnittelu, toteutus, käyttö ja huolto | DIN EN 806, osa 1–5 |

Käyttövesijärjestelmien suunnittelu, toteutus, käyttö ja huolto | DIN EN 1717 |

Käyttövesijärjestelmien suunnittelu, toteutus, käyttö ja huolto | DIN 1988 |

Käyttövesijärjestelmien suunnittelu, toteutus, käyttö ja huolto | VDI/DVGW 6023 |

Käyttövesijärjestelmien suunnittelu, toteutus, käyttö ja huolto | Trinkwasserverordnung (TrinkwV) |

Käyttövesijärjestelmien suunnittelu, toteutus, käyttö ja huolto | DVGW-Arbeitsblatt W 553 |

Säännökset osiosta: Aineet

Voimassaoloalue/ohje | Saksassa voimassa oleva säännös |

|---|---|

Soveltuvuus käyttövedelle | Trinkwasserverordnung (TrinkwV) |

Soveltuvuus käyttövedelle | DIN 1988‑200 |

Soveltuvuus käyttövedelle | EN 806‑2 |

Säännökset osiosta: Tuotteen kuvaus

Voimassaoloalue/ohje | Saksassa voimassa oleva säännös |

|---|---|

Käytettävyys käyttövedelle | DIN 50930‑6 |

Käytettävyys käyttövedelle | Trinkwasserverordnung (TrinkwV) |

Ympäristöviraston arviointiohjeet | Konformitätsbestätigung der trinkwasserhygienischen Eignung von Produkten nach System 1+ |

Säännökset osiosta: Yhteensopivat rakenneosat

Voimassaoloalue/ohje | Saksassa voimassa oleva säännös |

|---|---|

Puristusliitinten tarkastus ja hyväksyntä | DVGW-Arbeitsblatt W 534 |

Puristusliitinten tarkastus ja hyväksyntä käyttöön kupariputkien kanssa | DVGW-Arbeitsblatt GW 392 |

Puristusliitinten tarkastus ja hyväksyntä käyttöön kupariputkien kanssa | DIN EN 1057 |

Puristusliitinten tarkastus ja hyväksyntä käyttöön haponkestävien putkien kanssa (materiaali 1.4401 / 1.4521) | DVGW-Arbeitsblatt GW 541 |

Puristusliitinten tarkastus ja hyväksyntä käyttöön haponkestävien putkien kanssa (materiaali 1.4401 / 1.4521) | DIN EN 10312 |

Puristusliitinten tarkastus ja hyväksyntä käyttöön haponkestävien putkien kanssa (materiaali 1.4401 / 1.4521) | DIN EN 10088 |

Muoviputken tarkastus ja hyväksyntä | DVGW-työpaperi W544 |

Monikerrosputkien puristusliittimien testaus ja hyväksyntä | DVGW-CERT PEG-W001 |

Monikerrosputkien puristusliittimien testaus ja hyväksyntä | DVGW-CERT ZP 8803 |

Säännökset osiosta: Asennusohjeet

Voimassaoloalue/ohje | Saksassa voimassa oleva säännös |

|---|---|

Käyttövesiasennusten puhdistus ja desinfiointi | DVGW Arbeitsblatt 557 |

Säännökset osiosta: Tiiviystarkastus

Voimassaoloalue/ohje | Saksassa voimassa oleva säännös |

|---|---|

Tiiviystarkastuksia koskevat säännökset | DIN EN 806‑4 |

Tiiviystarkastuksia koskevat säännökset | ZVSHK Merkblatt "Dichtheitsprüfungen von Trinkwasserinstallationen mit Druckluft, Inertgas oder Wasser" |

Tiiviystarkastuksia koskevat säännökset (kuormitus- ja tiiviystarkastus) | Anforderungen / Bestimmungen der verantwortlichen Klassifizierungsgesellschaft(en) |

Tiiviystarkastuksia koskevat säännökset (kuormitus- ja tiiviystarkastus) | Standarddrucktests des ausführenden Betriebs (Werft) |

Säännökset osiosta: Huolto

Voimassaoloalue/ohje | Saksassa voimassa oleva säännös |

|---|---|

Käyttövesijärjestelmien käyttö ja huolto | DIN EN 806‑5 |

Määräysten mukainen käyttö

INFO!

Puristusliitosjärjestelmä soveltuu käyttövesiasennuksien tekemiseen voimassa olevien ohjeistuksien mukaisesti, kun materiaalin valinta tehdään voimassa olevien ohjeistuksien mukaisesti ja Saksan liittovaltion ympäristöviraston antaman arviontiperusteen pohjalta koskien käyttöveden kanssa kosketuksiin joutuvia materiaaleja, katso Säännökset osiosta: Käyttöalueet . Jos tuotetta käytetään muihin käyttötarkoituksiin tai jos oikeasta materiaalin valinnasta on epävarmuutta, käänny Viegan puoleen.

Käyttöalueet

Smartloop-Inliner-tekniikkaa käytetään sisällä olevana kiertojohtona käyttövesiasennuksissa. Järjestelmä sopii erityisesti lämpimän veden nousujohdoille ko’oissa d28, d32 ja d35.

Käyttövesijärjestelmien suunnittelua, toteutusta, käyttö ja huoltoa varten katso yleisesti tunnustetut tekniset säännöt täältä Säännökset osiosta: Käyttöalueet .

Käyttövesilaitteiston suunnitteluun Smartloop-Inliner-tekniikalla Viega suosittelee Viega Viptool-suunnitteluohjelmiston käyttöä.

Aineet

Järjestelmä soveltuu seuraaville aineille:

Käyttövesi

kloridipitoisuus enintään 250 mg/l (käyttövesiasetuksen mukaisesti)

Tuotekuvaus

Smartloop-Inliner-tekniikkaa voidaan käyttää käyttövesiasennuksissa sovellettavien ohjeiden mukaisesti, katso Säännökset osiosta: Tuotteen kuvaus .

Muovikomponentit vastaavat voimassa olevia määräyksiä, katso Säännökset osiosta: Tuotteen kuvaus

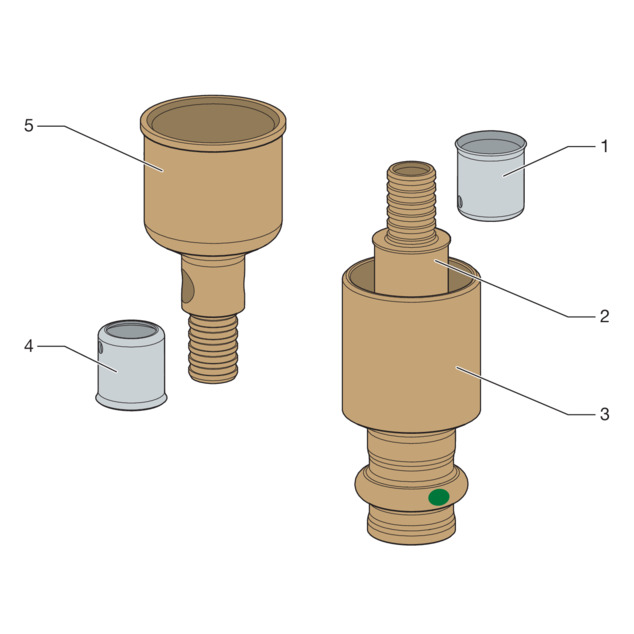

Yleiskatsaus

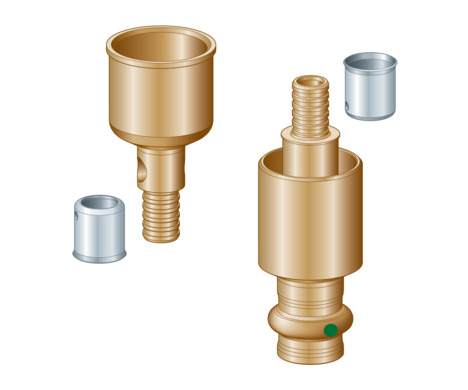

Smartloop-järjestelmä muodostuu seuraavista komponenteista:

Smartloop-liitossarja (malli 2276.1)

Smartloop-putki (malli 2007.3)

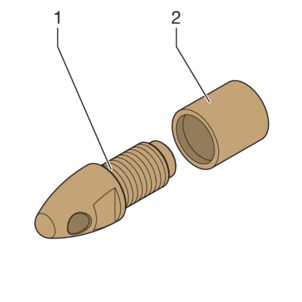

Smartloop-vetoliitin (malli 2276.9)

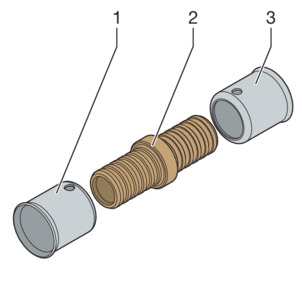

Smartloop-korjausliitin (malli 2276.8)

Järjestelmäkomponentteja on saatavana seuraavina kokoina:

Päätykappale-/liitososa d = 28, 35, 28 / 35

Smartloop-putki d12

- 1 - Puristusholkki

- 2 - Supistusliitin

- 3 - Liitososa

- 4 - Puristusholkki

- 5 - Päätekappale

- 1 - Vetopää

- 2 - Tukiholkki

- 1 - Puristusholkki

- 2 - Korjausliitin

- 3 - Puristusholkki

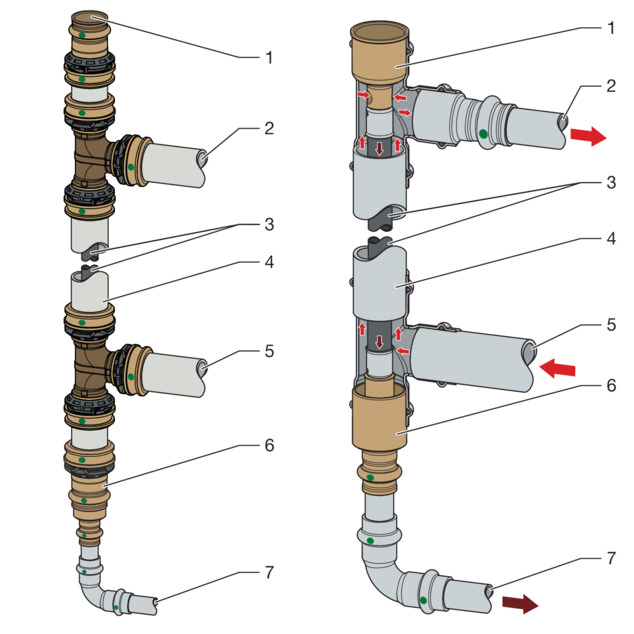

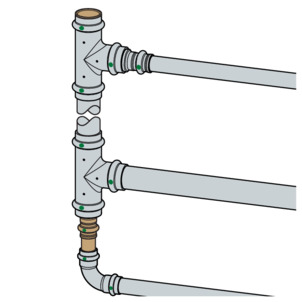

Toimintatavat

- 1 Päätekappale

- 2 Kerrosliitosjohto, lämminvesi

- 3 Sisäänasennettu kiertojohto

- 4 Lämpimän veden nousujohto

- 5 Kuumaveden jakelujohto

- 6 Liitososa

- 7 Kierron jakoputki

Kierto saadaan lämpimän veden putkessa aikaan seuraavasti: Lämmin vesi yhdistetään lämpimän veden jakotukkiin (5). Lämmin vesi virtaa lämpimän veden nousujohdossa (4) kerrosliitosjohtoihin (2). Kerrosliitosjohdon (2) viimeiseen T-yhteeseen kiinnitetyssä päätekappaleessa (1) olevan aukon kautta varmistetaan, että lämmin vesi virtaa sisällä olevan kiertojohdon (3) läpi ja kiertää näin kierron jakoputken kautta. Takaisin virtaavan veden lämpötila on korkeampi kuin perinteisissä kiertovesijärjestelmissä, mikä puolestaan tarjoaa energiaetuja.

Yhteensopivat rakenneosat

Mallissa on puristusliitännät, ja se sopii yhteen seuraavien järjestelmien kanssa:

Profipress

Sanpress

Sanpress Inox

Raxofix

Putket

Puristusliitännät on tarkastettu ja hyväksytty seuraaville putkityypeille voimassa olevien määräysten mukaisesti (katso myös kohta Säännökset osiosta: Yhteensopivat rakenneosat ):

Kupariputket

Haponkestävä teräsputki (materiaali 1.4401/1.4521)

Kerrosputket

Tekniset tiedot

Noudata seuraavia käyttöolosuhteita järjestelmän asennuksessa:

Käyttölämpötila |

|---|

Käyttöpaine |

Huomautuksia |

70 °C Tmax: 95 °C tmax: 60 min 1) |

1,0 MPa (10 baaria) |

katso Ohjeita Aineet |

| 1) | voimassa olevien säännösten mukaisesti (katso kohta Säännökset osiosta: Määräysten mukainen käyttö ) |

INFO!

Puristusliitosjärjestelmän tiivistysaineisiin kohdistuu lämpövanhenemista, joka riippuu ainelämpötilasta sekä käyttöajasta. Mitä korkeampi väliaineen lämpötila on, sitä nopeammin tiivistemateriaalin terminen vanheneminen etenee. Tietyissä käyttöolosuhteissa, kuten teollisissa lämmöntalteenottolaitteissa, on tarpeen sovittaa laitevalmistajan tiedot yhteen puristusliitosjärjestelmän tietojen kanssa.

Käänny Viegan puoleen, ennen kuin puristusliitosjärjestelmää käytetään muihin kuin kuvattuihin käyttötarkoituksiin tai jos oikean materiaalin valinnasta on epävarmuutta.

Käsittely

Asennustiedot

Asennusohjeet

Järjestelmäkomponenttien tarkastaminen

INFO!

Varmista mahdollisimman suuri puhtaus putken asennuksessa (katso kohta Säännökset osiosta: Asennusohjeet ).

Ota osat pakkauksesta vasta välittömästi ennen käyttöä.

Kuljetus ja varastointi on saattanut aiheuttaa järjestelmäkomponentteihin vaurioita.

Tarkasta kaikki osat.

Vaihda vaurioituneet komponentit.

Älä korjaa vaurioituneita komponentteja.

Likaantuneita komponentteja ei saa asentaa.

INFO!

Tietoja putkiston vetämisestä ja kiinnityksestä sekä pituuslaajenemisesta löytyy kunkin järjestelmän käyttöohjeista.

Tarvittava työkalu

Puristusliitäntä

INFO!

Puristukseen Viega suosittelee käytettäväksi Viega-järjestelmätyökaluja.

Viega puristusjärjestelmätyökalut on suunniteltu ja tarkoitettu erityisesti Viega puristusliitosjärjestelmien puristamiseen.

Smartloop-putki

Smartloop-putken asennukseen tarvitaan seuraavat työkalut:

Putkisakset, malli 5341

Asennuspihdit, malli 1077.2

Käsikäyttöinen puristustyökalu, malli 2782, tai puristusleuat, malli 2799.7

Asennus

Asenna Smartloop

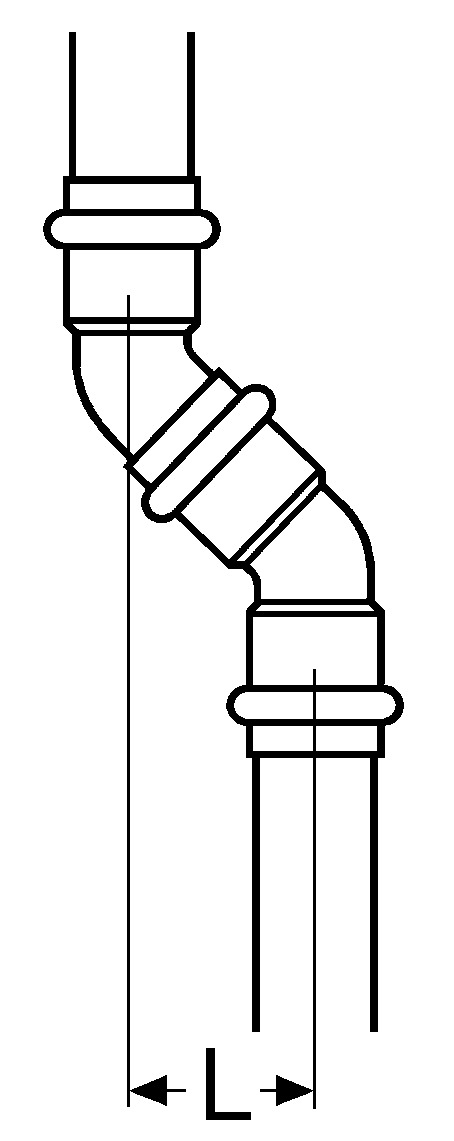

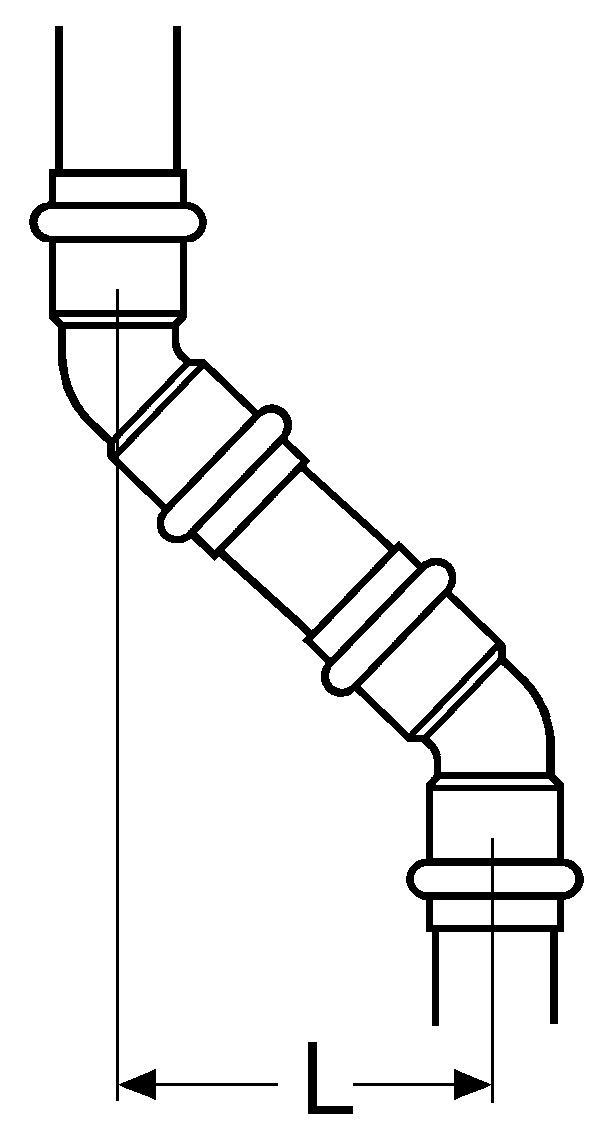

Lämpimän veden nousujohdon suurin siirtymä

Siirtymä1) |

|---|

Uudelleenohjaus L [mm] |

Tarvittavat osat |

Lukumäärä |

|  |

≥40–45 | ≥45–500 |

1 käyrä 45° 1 käyrä 45° ja pistopää | 2 käyrää 45° |

Suorita vain yksi siirtymä putkea kohden. | |

| 1) | Siirtymä voidaan tehdä vain metalliputkijärjestelmissä. |

Koordinoi muut kuin esitetyt asennusvaihtoehdot Viega huoltokeskuksen kanssa.

Toimintatavat

INFO!

Seuraavat asennusvaiheet näyttävät puristamisen käsityökalulla. Vaihtoehtoisesti voidaan käyttää sopivaa Viega puristuskonetta, jossa on asianmukaiset puristusleuat Tarvittava työkalu .

Edellytykset:

Nousuputki on muodostettu.

Nousuputki koostuu hyväksytyistä putkista (katso Yhteensopivat rakenneosat ).

Nousuputken koko on vähintään d28 ja enintään d35.

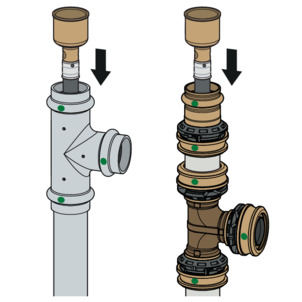

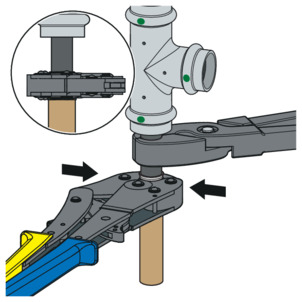

-

Valmistele putki asennusta varten.

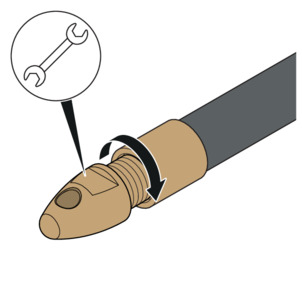

Asenna mallin 2276.9 asennusliitin putken päähän kiintoavaimella (SW 10).

-

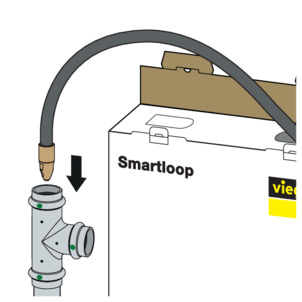

Työnnä putki yläkautta lämpimän veden nousujohtoon.

OHJE!Älä käytä putken asettamiseen rasvaa tai voiteluaineita.

Putken on työnnyttävä ulos nousujohdon alapäädystä n. 30 cm.

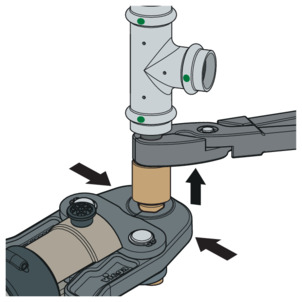

-

Katkaise putki pituuteen suorassa kulmassa.

-

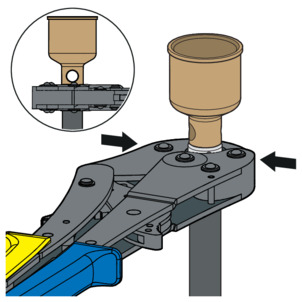

Työnnä puristusholkki putken ylempään päähän.

-

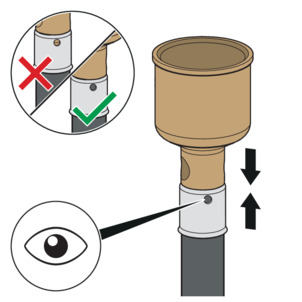

Vie päätekappale Smartloop-putkeen.

-

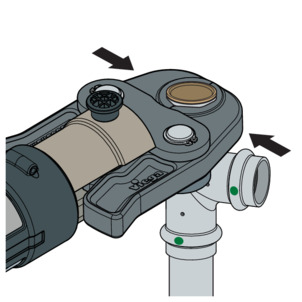

Tarkasta pistosyvyys tarkastusaukosta.

-

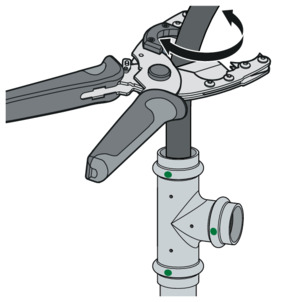

Käytä puristustyökalua oikeassa kulmassa.

-

Purista käsikäyttöisellä puristustyökalulla, kunnes pihdit aukeavat.

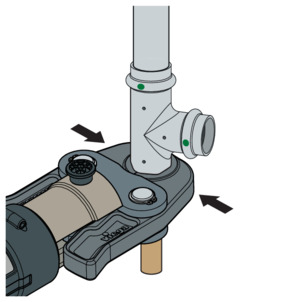

-

Laita päätekappale lämpimän veden nousujohdon ylempään T-kappaleeseen.

Käytä tarvittaessa supistusta.

-

Purista liitos.

-

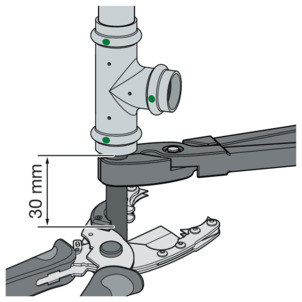

Vedä putki alapäästä asennuspihdeillä kireälle.

-

Pidä putki edelleen kireänä ja katkaise se 30 mm T-yhteen alapuolelta.

-

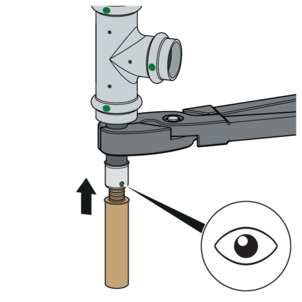

Työnnä puristusholkki putken alempaan päähän.

-

Laita yhdistäjä putkeen.

-

Tarkasta pistosyvyys tarkastusaukosta.

-

Käytä puristustyökalua oikeassa kulmassa.

-

Purista käsikäyttöisellä puristustyökalulla, kunnes pihdit aukeavat.

-

Työnnä liitososa vasteeseen saakka yhdistäjään ja purista paikoilleen.

-

Poista jälleen asennuspihdit.

-

Työnnä liitososa vasteeseen saakka lämpimän veden nousujohdon alempaan T-kappaleeseen ja purista paikoilleen.

-

Liitä lämpimän veden nousujohto ja kiertojohto kulloisiinkin kellarin jakelu- ja keruuputkiin.

-

Suorita tiiviystarkastus.

-

Kiinnitä ohjekyltti ”Sisäinen kiertojohto” näkyvästi valmiiseen lämpimän veden nousujohtoon.

Tiiviystarkastus

Ennen käyttöönottoa asentajan on suoritettava tiiviystarkastus.

Suorita tämä tarkastus valmiiksi tehdylle, mutta ei vielä peitetylle järjestelmälle.

Noudata yleisesti voimassa olevia tekniikan sääntöjä ja voimassa olevia määräyksiä, katso Säännökset osiosta: Tiiviystarkastus .

Dokumentoi tulos.

Huolto

OHJE!

Ilmoita toimeksiantajallesi tai käyttövesijärjestelmän käyttäjäyritykselle, että laitteisto on huollettava säännöllisesti.

Nousuputken korjaaminen

INFO!

Korjaustilanteissa ota yhteyttä Viega huoltokeskukseen.

Hävittäminen

Lajittele tuote ja pakkaus vastaaviin materiaaliryhmiin (esim. paperit, metallit, muovit tai muut kuin rautametallit) ja hävitä ne kansallisesti voimassa olevien lakien mukaisesti.