Viega Smartpress

Product information

Viega Smartpress

| Year built (from): | 01/04/2016 |

Trade mark rights exist for this document; for further information, go to viega.com/legal .

Target groups

The information in this manual is directed at heating and sanitary professionals and trained personnel.

Individuals without the abovementioned training or qualification are not permitted to mount, install and, if required, maintain this product. This restriction does not extend to possible operating instructions.

The installation of Viega products must take place in accordance with the general rules of engineering and the Viega instructions for use.

Labelling of notes

Warning and advisory texts are set aside from the remainder of the text and are labelled with the relevant pictographs.

DANGER!

This symbol warns of possible life-threatening injury.

WARNING!

This symbol warns of possible serious injury.

CAUTION!

This symbol warns of possible injury.

NOTICE!

This symbol warns of possible damage to property.

INFO!

This symbol gives additional information and hints.

About this translated version

This instruction for use contains important information about the choice of product or system, assembly and commissioning as well as intended use and, if required, maintenance measures. The information about the products, their properties and application technology are based on the current standards in Europe (e.g. EN) and/or in Germany (e.g. DIN/DVGW).

Some passages in the text may refer to technical codes in Europe/Germany. These should serve as recommendations in the absence of corresponding national regulations. The relevant national laws, standards, regulations, directives and other technical provisions take priority over the German/European directives specified in this manual: The information herein is not binding for other countries and regions; as said above, they should be understood as a recommendation.

Standards and regulations

The following standards and regulations apply to Germany / Europe and are provided as a support feature.

Regulations from section: Application areas

Scope / Notice | Regulations applicable in Germany |

|---|---|

Planning, execution, operation and maintenance of potable-water installations | DIN EN 1717 |

Planning, execution, operation and maintenance of potable-water installations | DIN 1988 |

Planning, execution, operation and maintenance of potable-water installations | VDI/DVGW 6023 |

Planning, execution, operation and maintenance of potable-water installations | Trinkwasserverordnung (TrinkwV) |

Regulations from section: Chemical resistance

Scope / Notice | Regulations applicable in Germany |

|---|---|

Regulations for external corrosion protection | DIN EN 806, Part 2 |

Regulations for external corrosion protection | DIN 1988 |

Regulations for external corrosion protection | DIN 1988‑200 |

Regulations from section: Storage

Scope / Notice | Regulations applicable in Germany |

|---|---|

Requirements for material storage | DIN EN 806‑4, Chapter 4.2 |

Regulations from section: Leakage test

Scope / Notice | Regulations applicable in Germany |

|---|---|

Test on a system that is finished but not yet covered | DIN EN 806–4 |

Leakage test for water installations | ZVSHK-Merkblatt: |

Regulations from section: Maintenance

Scope / Notice | Regulations applicable in Germany |

|---|---|

Operation and maintenance of potable water installations | DIN EN 806‑5 |

Intended use

INFO!

Agree the use of the system for areas of application and media other than those described with Viega.

Areas of application

Use is possible in the following areas among others:

Viega Smartpress multi-layer pipe (dimensionally stable with oxygen barrier layer)

potable water installations

Heating installations

Compressed air systems

Potable-water installation

Observe the applicable guidelines for planning, installation, operation and maintenance of potable water installations, see Regulations from section: Application areas .

Maintenance

Inform your customer or the operator of the potable water installation that the system has to be maintained on a regular basis, see Regulations from section: Application areas .

Installation surroundings

The system is only intended for installation inside buildings.

Use of the system outside or in special surroundings must be agreed with the Viega Service Center.

Media

The system is suitable for the following media, amongst others:

Viega Smartpress multi-layer pipe (dimensionally stable with oxygen barrier layer)

Potable water

Rainwater

Heating water

Compressed air

Operating conditions

Operating temperature max.

Sanitary installations: TD 70 °C

Heating installations: TD 80 °C

Operating pressure max.

Sanitary installations: 1.0 MPa (10 bar)

Heating installations: 1.0 MPa (10 bar)

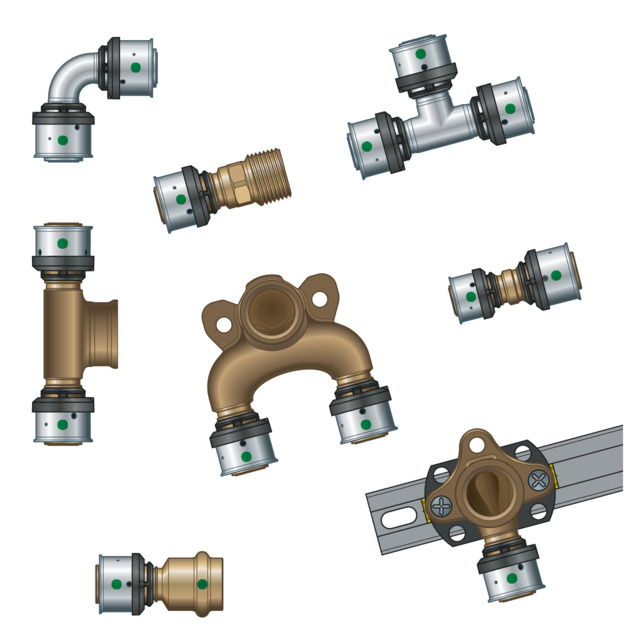

Product description

Overview

The piping system consists of various pipes and press connectors.

The system components are available in the following dimensions: d 16 / 20 / 25 / 32 / 40 / 50 / 63.

Pipes

The following pipes are available from the system described:

Viega Smartpress multi-layer pipes, with or without protective pipe, with various thicknesses of insulation are available in coiled bundles. Dimensionally stable multi-layer pipes are also available in 5 m lengths. The following pipes are available from the system described:

Viega Smartpress multi-layer pipe |

|---|

Dimensionally stable |

With oxygen barrier layer |

d 16, 20, 25, 32, 40, 50, 63 |

Viega Smartpress multi-layer pipe

Type of pipe |

|---|

Pipe in lengths |

Pipe without protective pipe |

Pipe with protective pipe (black, blue, red) |

Pipe with 6 mm surrounding insulation (blue) |

Pipe with 9 mm surrounding insulation (blue) |

d | Areas of application |

|---|---|

16, 20, 25, 32, 40, 50, 63 | Potable water and heating installations |

16, 20, 25, 32 | Potable water and heating installations |

16, 20, 25 | Potable water and heating installations |

16, 20 | Potable water and heating installations |

25 | Potable water and heating installations |

Viega Smartpress multi-layer pipe |

|---|

Dimensionally stable |

With oxygen barrier layer |

d 16, 20 |

Viega Smartpress multi-layer pipe

Type of pipe |

|---|

Pipe without protective pipe |

Pipe with protective pipe (black) |

Pipe with 6 mm surrounding insulation (blue) |

Pipe with 9 mm surrounding insulation (grey) |

d | Areas of application |

|---|---|

16, 20 | Potable water and heating installations |

16, 20 | Potable water and heating installations |

16, 20 | Potable water and heating installations |

16, 20 | Potable water and heating installations |

Laying and fixing pipes

Only pipe clamps with chloride-free sound insulating inlays should be used to secure the pipes.

Observe the general rules of fixing technology:

Do not use fixed pipelines as a support for other pipelines and components.

Do not use pipe hooks.

Observe distance to press connectors.

Observe the expansion direction: Plan fixed and gliding points.

Make sure to affix the pipelines in such a way as to de-couple them from the installation body, so that they cannot transfer any structure-borne sound, resulting from thermal expansion or possible pressure surges, onto the installation body or other components.

Observe the following fixing distances:

Distance between the pipe clamps

d x s [mm] |

|---|

16 x 2.0 |

20 x 2.3 |

25 x 2.8 |

32 x 3.2 |

40 x 3.5 |

50 x 4.0 |

63 x 4.5 |

Horizontal Multi-layer pipe [m] | Vertical Multi-layer pipe [m] |

|---|---|

1.00 | 1.30 |

1.00 | 1.30 |

1.50 | 1.95 |

2.00 | 2.60 |

2.00 | 2.60 |

2.50 | 3.25 |

2.50 | 3.25 |

Length expansion

Pipelines expand with heat. Heat expansion is dependent on the material. Changes in length lead to tension within the installation. These tensions must be compensated for with suitable measures.

The following are effective:

Fixed and gliding points

Expansion equalisation joints (expansion bends)

Heat expansion co-efficients of various pipe materials

Material | Heat expansion co-efficient ⍺ | Example: |

|---|---|---|

Viega Smartpress multi-layer pipe | 0.03 | 30 |

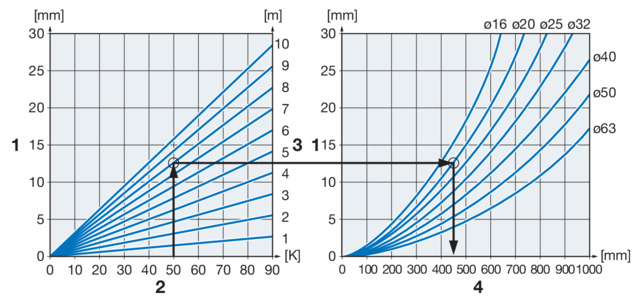

Length expansion and expansion bend length

Calculation example multi-layer pipe

Given: Temperature difference Δ ϑ = 50 K; pipe length L = 8 m; pipe Ø = 20 mm

Required: Expansion bend lengthLBS

Calculation:

Beginning in the left-hand diagram: From 50 K temperature difference on the x-axis up to the characteristic line for the 8 m pipe length.

Connect the intersection horizontally with the right-hand diagram up to the intersection of the characteristic line for pipe diameter 20 mm.

Result: Read the value from the x-axis:LBS = 480 mm.

- 1 - Length expansion ∆l [mm]

- 2 - Temperature difference ∆ϑ [K]

- 3 - Pipe length L [m]

- 4 - Expansion bend length LBS [mm]

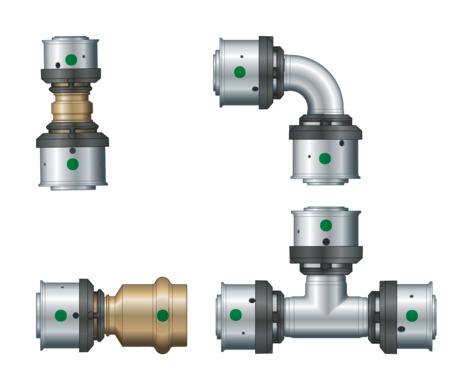

Press connectors

The press connectors of the Viega Smartpress system consist of the following materials:

Gunmetal/silicon bronze

Stainless steel

PPSU

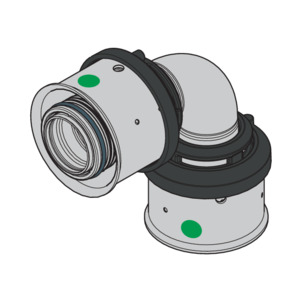

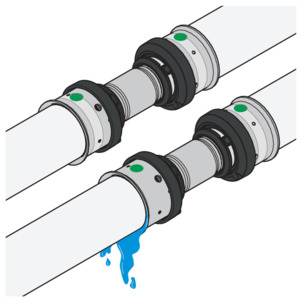

SC‑Contur

Viega press connectors are equipped with the SC‑Contur. SC‑Contur is a safety mechanism certified by the DVGW and ensures that the press connector leaks in an unpressed state. In this way, inadvertently unpressed connections are noticed during a leakage test.

Viega guarantees that accidentally unpressed connections become visible during a leakage test:

with the wet leakage test in the pressure range from 0.1–0.65 MPa (1.0–6.5 bar)

with dry leakage test in the pressure range from 22 hPa–0.3 MPa (22 mbar–3.0 bar)

Markings on components

Pipe marking

The pipe markings contain important information regarding the quality and certification of the pipes. Their meaning is as follows:

Manufacturer

System name

Pipe material

Size / wall thickness

Certification and operating temperatures

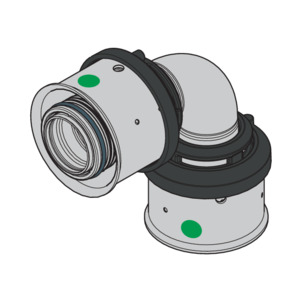

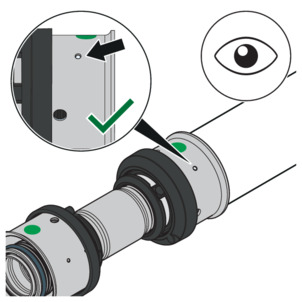

Markings on press connectors

The press connectors are marked with a coloured dot. The dot identifies the SC‑Contur where the test medium would escape in the case of an inadvertently unpressed connection.

The green dot shows that the press connector is equipped with the SC‑Contur and that the system is suitable for potable water.

Mixed installations

Permitted mixed installations

To ensure proper function, the Viega Smartpress press connectors may be used only with the Viega pipes from the Viega Smartpress, Pexfit Pro, and Pexfit Fosta systems. Since the use with pipes of other systems or by other manufacturers has not been tested, proper function cannot be ensured in this case.

Installation of Viega Smartpress pipes with old Pexfit Fosta press connectors is not possible.

Please contact Viega for questions on this subject.

Information for use

Chemical resistance

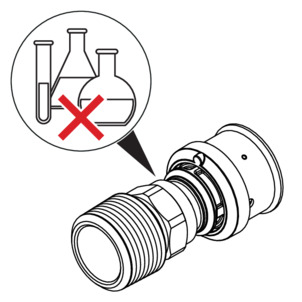

NOTICE!

Damage to material due to aggressive chemicals

Aggressive chemicals, especially those containing solvents, may cause material damage and leaks. This may lead to water damage.

Prevent contact between the system components and aggressive chemicals.

NOTICE!

Material damage due to impermissible leakage detection agents

Impermissible leakage detection agents may cause material damage and leaks. This may lead to water damage.

Use only leakage detection agents approved by the manufacturer for use on PPSU material.

Observe the manufacturer's notes on processing.

Protect the system components against excessively high concentrations of chloride in the medium or in the operational environment. An excessive chloride concentration can lead to corrosion in stainless steel systems.

The chloride concentration in the medium must not exceed a maximum value of 250 mg/l.

The following rules apply for avoiding external contact with materials containing chloride:

Insulating materials must not have a water-soluble chloride ion content by weight that exceeds 0.05 %.

The sound insulating inlays on the pipe clamps must not contain leachable chloride.

Stainless steel components must not come into contact with building materials or mortar containing chloride.

If external corrosion protection is required, observe the general rules of engineering, see Regulations from section: Chemical resistance .

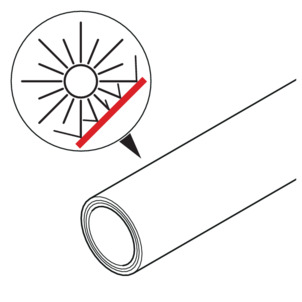

NOTICE!

Material damage due to UV radiation

Permanent UV radiation can lead to material damage and leaks. This may lead to water damage.

Do not expose the pipes to permanent UV radiation.

Handling

Storage

For storage, comply with the requirements specified in the applicable regulations, see Regulations from section: Storage :

Store rods on even, clean surfaces.

Storage outside in closed, original packaging is possible for a period of up to three months. In this instance, protect the packaging from damage due to rain or high levels of humidity or UV radiation.

Assembly information

Mounting instructions

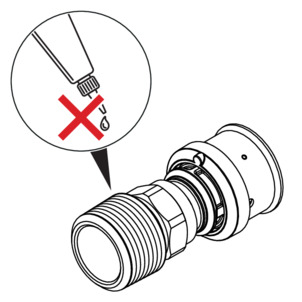

NOTICE!

Material damage due to thread locker containing solvents!

Thread lockers containing solvents can lead to material damage and leaks in plastic parts of pipe connections. This may lead to water damage.

As a sealant, only use commercially available hemp together with thread sealing paste or certified sealing tape for potable water.

Please contact the Viega Service Center if you have any questions.

Checking system components

System components may, in some cases, have become damaged through transportation and storage.

Check all parts.

Replace damaged components.

Do not repair damaged components.

Contaminated components may not be installed.

Space requirements and intervals

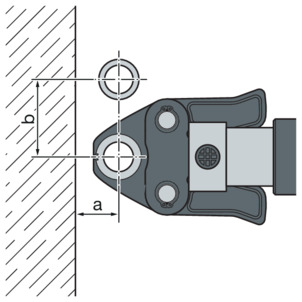

Pressing between pipelines

Space required Type 2 (PT2), PT3-EH, PT3-AH, Pressgun 4B, 4E, 5, 6, 6 Plus

d |

|---|

a [mm] |

b [mm] |

16 | 20 | 25 | 32 | 40 | 50 | 63 |

|---|---|---|---|---|---|---|

15 | 16 | 23 | 21 | 28 | 40 | 56 |

45 | 45 | 58 | 65 | 70 | 85 | 125 |

Space requirement Picco, Pressgun Picco, Pressgun Picco 6, Pressgun Picco 6 Plus

d |

|---|

a [mm] |

b [mm] |

16 | 20 | 25 | 32 |

|---|---|---|---|

15 | 15 | 20 | 25 |

48 | 50 | 55 | 70 |

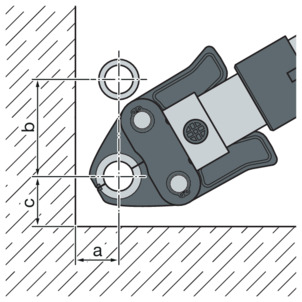

Pressing between pipe and wall

Space required Type 2 (PT2), PT3-EH, PT3-AH, Pressgun 4B, 4E, 5, 6, 6 Plus

d |

|---|

a [mm] |

b [mm] |

c [mm] |

16 | 20 | 25 | 32 | 40 | 50 | 63 |

|---|---|---|---|---|---|---|

20 | 20 | 25 | 30 | 35 | 40 | 54 |

76 | 76 | 80 | 90 | 92 | 95 | 140 |

25 | 25 | 35 | 35 | 43 | 55 | 61 |

Space requirement Picco, Pressgun Picco, Pressgun Picco 6, Pressgun Picco 6 Plus

d |

|---|

a [mm] |

b [mm] |

c [mm] |

16 | 20 | 25 | 32 |

|---|---|---|---|

20 | 21 | 25 | 30 |

70 | 74 | 75 | 80 |

28 | 28 | 35 | 40 |

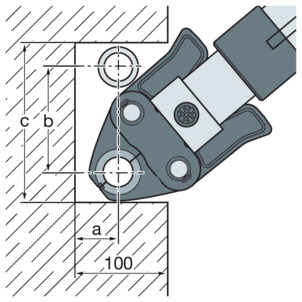

Pressing in wall slots

Space required Type 2 (PT2), PT3-EH, PT3-AH, Pressgun 4B, 4E, 5, 6, 6 Plus

d |

|---|

a [mm] |

b [mm] |

c [mm] |

16 | 20 | 25 | 32 | 40 | 50 | 63 |

|---|---|---|---|---|---|---|

20 | 20 | 25 | 30 | 35 | 40 | 54 |

90 | 90 | 90 | 95 | 92 | 95 | 140 |

140 | 140 | 140 | 155 | 178 | 205 | 262 |

Space requirement Picco, Pressgun Picco, Pressgun Picco 6, Pressgun Picco 6 Plus

d |

|---|

a [mm] |

b [mm] |

c [mm] |

16 | 20 | 25 | 32 |

|---|---|---|---|

20 | 21 | 25 | 30 |

80 | 80 | 80 | 80 |

120 | 120 | 120 | 160 |

Z dimensions

For the Z dimensions, refer to the respective product page in the online catalogue.

Required tools

The use of original Viega tools or equivalent tools is recommended for installation.

The following tools are required for production of a press connection:

INFO!

Hand or electric saws or angle grinders are not permitted.

Press machine with constant pressing force

Suitable Viega Smartpress press jaws for plastic piping systems (model 2799.7 or 2784.7)

Hand press tool (model 2782.5) for dimensions 16–25 mm

Pipe shear (model 5341 or model 2040) for dimensions 16–25 mm

Pipe cutters (model 2191) for dimensions 32–63 mm

Bending tool (model 5331.2)

INFO!

The hand press tool model 2782 (built before 08/2004) may not be used for Viega Smartpress press connectors.

Only use the current hand press tool model 2782.5 with ratchet function to press Viega Smartpress press connectors.

INFO!

Viega recommends the use of Viega system tools when installing the press fittings.

The Viega system press tools have been developed and tailored specifically for the installation of Viega press connector systems.

Assembly

Bending pipes

NOTICE!

Product damage due to use of metal internal bending springs

The use of metal internal bending springs can lead to damage to the pipe surface and to the introduction of contaminations into the installation.

Do not use metal internal bending springs.

Viega recommends using the Viega internal bending tool made of plastic (model 5331.2).

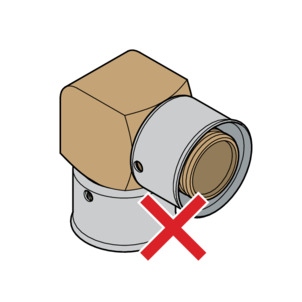

NOTICE!

Product damage when bending directly at the press connector

Extreme bending directly at the press connector may cause damage to pipe and press connector and leaks.

To avoid damage, choose a bending point with sufficient distance to the press connector.

Viega Smartpress multi-layer pipes in the dimensions 16–32 mm can be bent by hand with a bending radius of 5 x d or with a bending tool with the following radii:

d | Bending radius x d |

|---|---|

16 | 2.0 |

20 | 2.3 |

25 | 3.0 |

32 | 3.5 |

40 | 4.0 |

50 | 4.5 |

63 | 4.5 |

The recommended bending tools for dimensions d16 and 20 are the models 5331 and 5331.2.

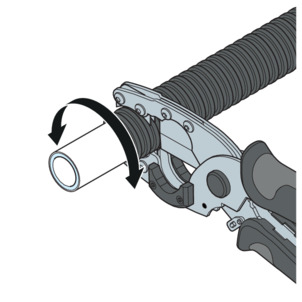

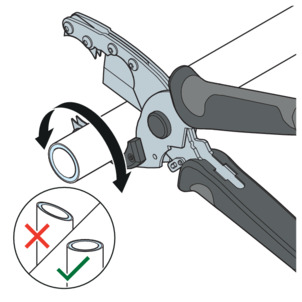

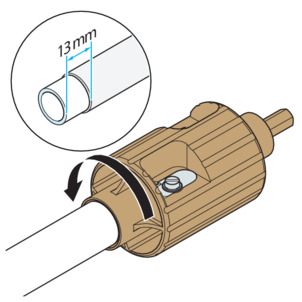

Cutting pipes to length

For information about tools, also see Required tools .

Dimensions 16–25 mm

-

Cut the protective pipe to length using the protective pipe cutter (model 5341).

-

Be careful not to damage the pipe.

-

Cut the pipe to length using a pipe shear.

Replace worn blades (model 5341.6 or 2040‑404).

Make sure that the cut surface is clean and straight.

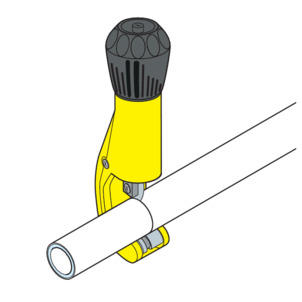

Dimensions 32–63 mm

-

Cut the pipe to length using a pipe cutter (model 2191).

Stripping pipes

When using Pexfit Fosta pipes model 2703; 2704; 2705; 2705.5; 2709 and 2709.1, remove a section the length of the press sleeve from the outside coating and the aluminium layer using the chamfer model 2758.5.

The use of other chamfer tools is not permitted.

-

Remove coating from the pipe end using a chamfer.

-

The length of the stripped pipe end corresponds to the insertion depth of the press connector.

INFO!

Replace the worn blades with model 2758.1.

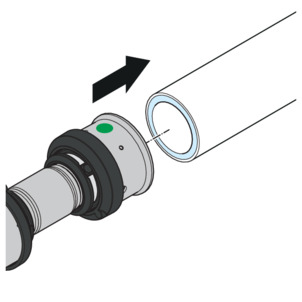

Pressing the connection

-

Push the pipe into the press connector until the pipe end is visible in the inspection window.

-

Check the insertion depth in the inspection window.

-

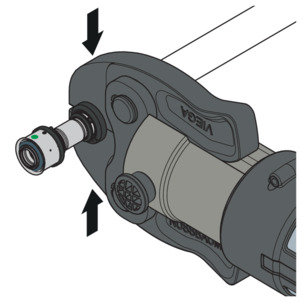

Open the press jaw and place it at a right-angle onto the press connector.

Observe the intervals in section Space requirements and intervals .

-

Carry out the pressing process.

-

Connection is pressed.

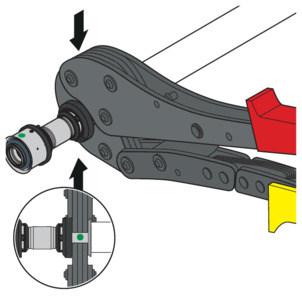

Alternatively: Press the connection with hand tool

-

Open the hand press tool and place it at a right-angle onto the press connector.

Observe the intervals in section Space requirements and intervals .

-

Carry out the pressing process.

-

Connection is pressed.

Leakage test

NOTICE!

Also refer to the information for use on leakage detection agents, see Chemical resistance .

The installer must perform a leakage test before commissioning.

Carry out this test on a system that is finished but not covered.

Observe the applicable regulations, see Regulations from section: Leakage test .

The leak test should also be carried out for non-potable water installations in accordance with the applicable guidelines, see Regulations from section: Leakage test .

Document the result.

Maintenance

Observe the applicable guidelines for the operation and maintenance of potable water installations, see Regulations from section: Maintenance .

Disposal

Separate the product and packaging materials (e. g. paper, metal, plastic or non-ferrous metals) and dispose of in accordance with valid national legal requirements.